Q-ONE POWER FEEDER IN OPERATION AT SHINKASAI STEEL, JAPAN

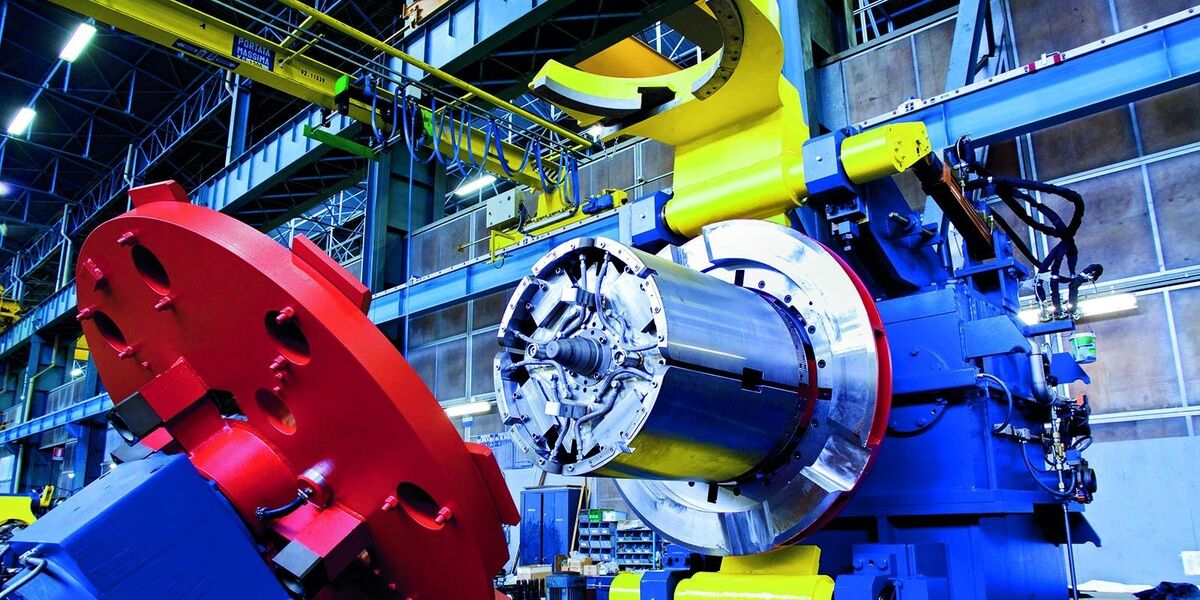

According to me-metals cited from mining.com, A second Danieli Q-One power feeder is in operation in Japan.

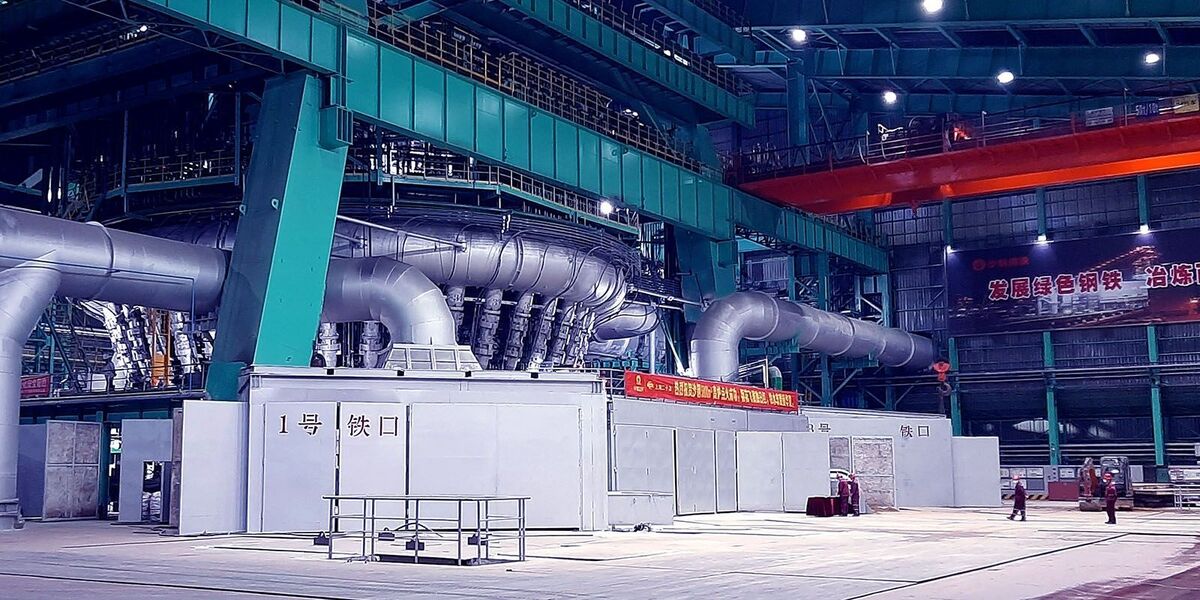

Thanks to the installation of the Q-One power feeder Shinkasai Steel is now operating a digital EAF in Osaka.

The start of operation was immediate and with the achievement of all the performance tests the Japanese steelmaker released the Final Acceptance Certificate -FAC in just 28 days from the startup.

Q-One allows a highly efficient EAF melting thanks to variable frequency operation down to 20 Hz in full power. This implies a strong, visible stirring within the liquid steel bath, leading to a power-on reduction and consequent energy savings of around 8%.

Another astonishing characteristic of the Q-One is the almost negligible impact on the power grid –without the need of any compensation system– making electric steelmaking viable in weak electric network conditions, like in the Osaka Sakai industrial area.

Specifically, the Pst flicker value is about 0.5 and the harmonics level is about 30% of maximum allowed.

Following the first Q-One power feeder installation in Japan at Tokyo Steel, in Kyushu, in 2021, and now the one at Shinkasai Steel, two more Q-One systems are scheduled to be started in Japan soon at Chiyoda Steel in Tokyo and JFE B&S in Himeji.

source: danieli.com

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Barrick’s Reko Diq in line for $410M ADB backing

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts