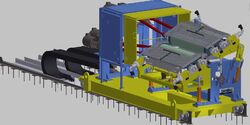

Roll-coating system improvements enhance strip coating control and accuracy

The upgrading – featuring DanCoaters installed in an horizontal configuration and related controls – resulted in improved control for accuracy and repeatability of the coating thickness, saving coating material and reducing scrap.

DanCoaters are equipped with an efficient system that provides full, continuous control of position and pressure, as well as the other coating parameters (such as roll speed), thus allowing a specific paint thickness to be applied evenly across the strip surface.

The new design also can be retrofitted to most manufacturers’ older machines, with minimal impact to production and downtime.

DanCoaters are designed to meet safety requirements while maintaining full equipment operation: nip feed guards, carters, safety switches, pins, foot walks, handrails, safety interlocks, etc., are designed in conjunction with the final customer’s needs in order to minimize potential hazards.

Danieli Service advisory and MMK maintenance teams executed the job during a maintenance shutdown thanks to accurate planning and a plug and work package.

Source: Danieli

SAIL Bhilai Steel relies on Danieli proprietary technology to expand plate mill portfolio to higher steel grades

Alba Discloses its Financial Results for the Second Quarter and H1 of 2025

Fortuna rises on improved resource estimate for Senegal gold project

Copper price slips as unwinding of tariff trade boosts LME stockpiles

US slaps tariffs on 1-kg, 100-oz gold bars: Financial Times

Fresnillo lifts gold forecast on strong first-half surge

Why did copper escape US tariffs when aluminum did not?

Codelco seeks restart at Chilean copper mine after collapse

NextSource soars on Mitsubishi Chemical offtake deal

Hudbay snags $600M investment for Arizona copper project

Discovery Silver hits new high on first quarterly results as producer

Trump says gold imports won’t be tariffed in reprieve for market

AI data centers to worsen copper shortage – BNEF

Uzbek gold miner said to eye $20 billion value in dual listing

Peabody–Anglo $3.8B coal deal on the brink after mine fire

De Beers strikes first kimberlite field in 30 years

Minera Alamos buys Equinox’s Nevada assets for $115M

OceanaGold hits new high on strong Q2 results

What’s next for the USGS critical mineral list

Hudbay snags $600M investment for Arizona copper project

Discovery Silver hits new high on first quarterly results as producer

Trump says gold imports won’t be tariffed in reprieve for market

AI data centers to worsen copper shortage – BNEF

Peabody–Anglo $3.8B coal deal on the brink after mine fire

De Beers strikes first kimberlite field in 30 years

Minera Alamos buys Equinox’s Nevada assets for $115M

OceanaGold hits new high on strong Q2 results

South Africa looks to join international diamond marketing push