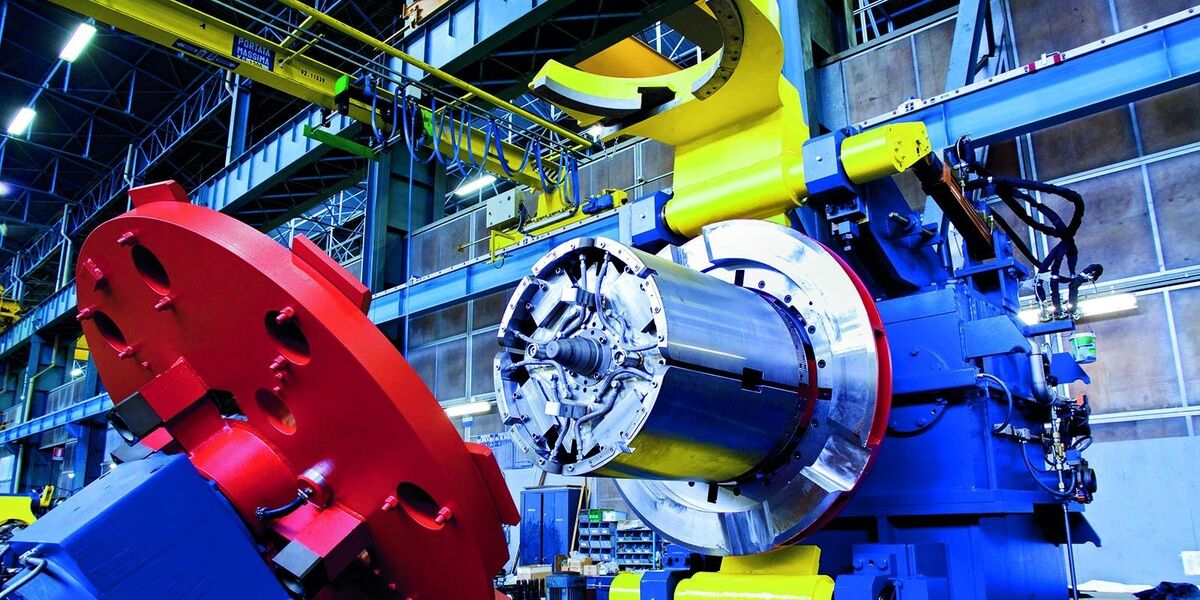

NEW STRAIGHTENING LINE FOR LARGE DIAMETERS AT ACCIAIERIE VENETE

According to me-metals cited from mining.com, Italian steelmaker Acciaierie Venete has renewed its choice in Danieli Centro Maskin technology, ordering a second straightening line to be installed at Padova Works, in Italy.

The new installation will consist of a fully automated, high-productivity straightening line to process SBQ black bars up to 200-mm-dia, having a max. yield strength of 1350 N/mm2.

The high-efficiency solution selected by Acciaierie Venete featuring Danieli Automation advanced equipment and process control integrated into a user-friendly interface that will allow up to 15% savings in energy consumption and line set-up time.

The unit is in compliance with Industry 4.0 and ready to be integrated with the latest generation of Danieli digital systems (D-CMS – Danieli Condition Monitoring System) at any time. Through the monitoring and analysis of the data acquired by the various sensors installed on the line, D-CMS is able to improve the overall process efficiency, eliminate unplanned maintenance, know proper action plans in advance, as well as optimize spare parts procurement and related investments.

Since 1970 Danieli has supplied more than 160 straightening and reeling lines for ferrous and nonferrous materials.

source: danieli.com

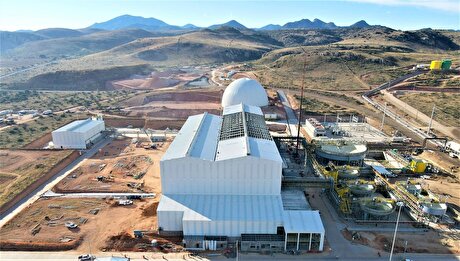

Barrick’s Reko Diq in line for $410M ADB backing

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Pan American locks in $2.1B takeover of MAG Silver

US adds copper, potash, silicon in critical minerals list shake-up

Gold price gains 1% as Powell gives dovish signal

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

Gold boom drives rising costs for Aussie producers

US seeks to stockpile cobalt for first time in decades

Giustra-backed mining firm teams up with informal miners in Colombia

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

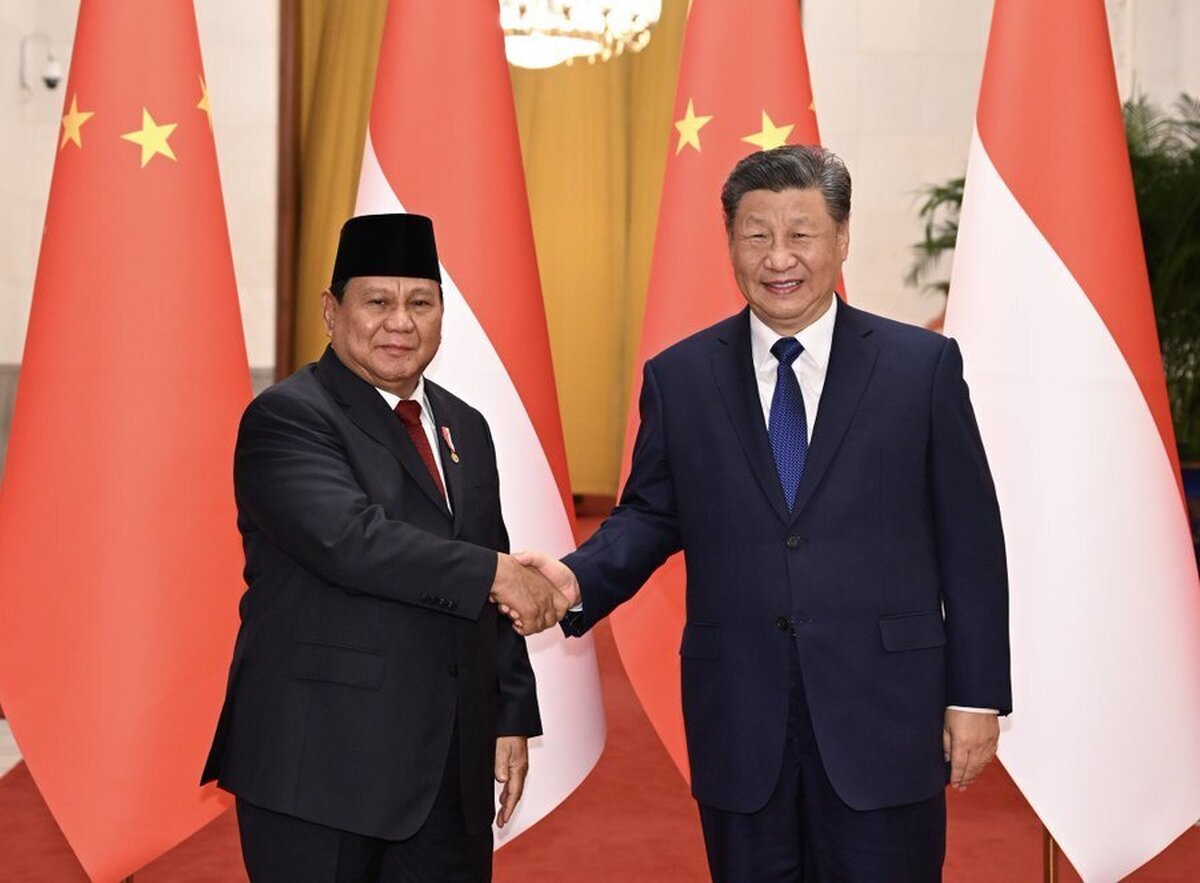

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook