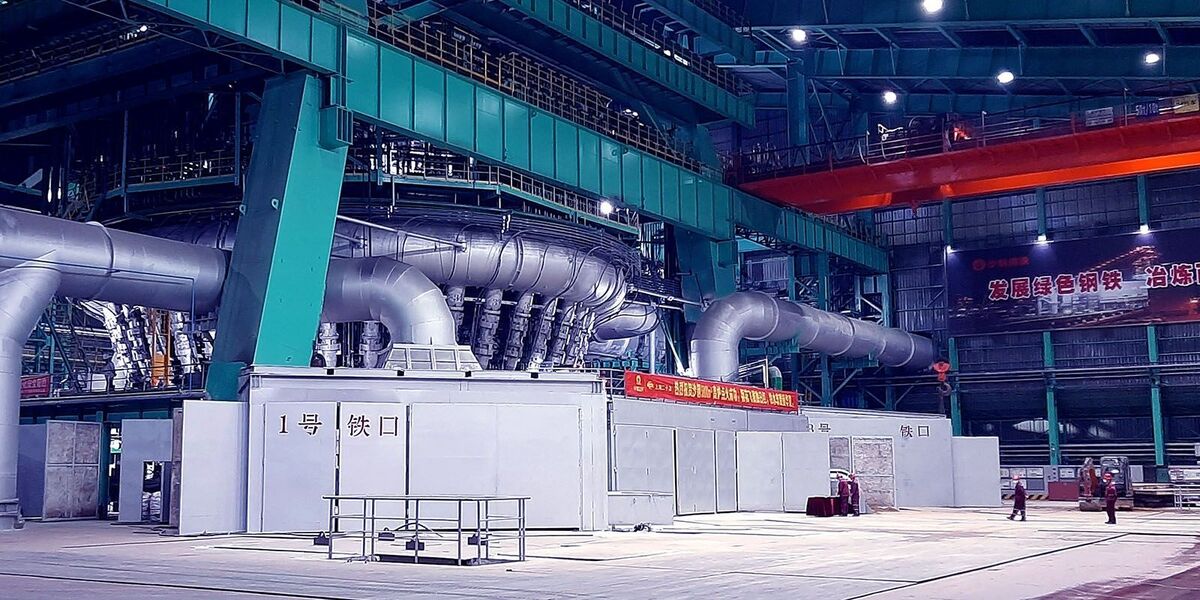

A new, significant technology milestone achieved by Danieli QSP-DUE plant at Yukun

According to me-metals cited from mining.com, This is an unprecedented slab thickness for a direct casting and rolling plant.

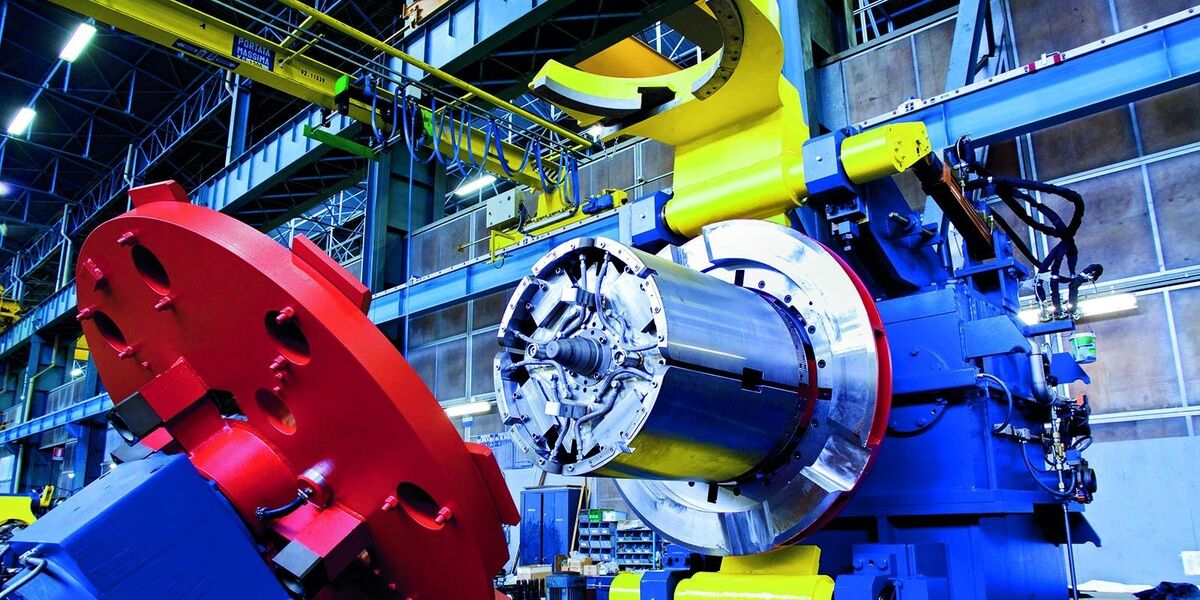

Such a groundbreaking milestone was achieved by using a 152-mm funnel mould, confirming the Danieli-patented DySen caster as benchmark slab-casting technology.

Increased slab thickness means improved overall strip quality thanks to a higher reduction ratio in the mill, and new possibilities in the application of the QSP-DUE process for the production of quality hot-rolled coils.

This achievement was possible thanks to the sturdiness and flexibility of Danieli equipment and automation, and the skill of the Yukun team.

The Danieli QSP-DUE plant of Yukun is designed to produce low- and medium-carbon, HSLA and medium-carbon high-alloyed grades in ultralight gauges down to 0.8 mm in endless mode, and very thick gauges of up to 25.4 mm in coil-to-coil mode.

Featuring two casting strands, and endless casting-rolling on one, for a production capacity exceeding 4.5 Mtpy of hot-rolled strip, the plant is the highest performing direct casting-rolling plant in the world.

source: danieli.com

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

EverMetal launches US-based critical metals recycling platform

Afghanistan says China seeks its participation in Belt and Road Initiative

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts