EXSTREAM II: THE DANIELI QUENCH SYSTEM FOR QUALITY PLATES

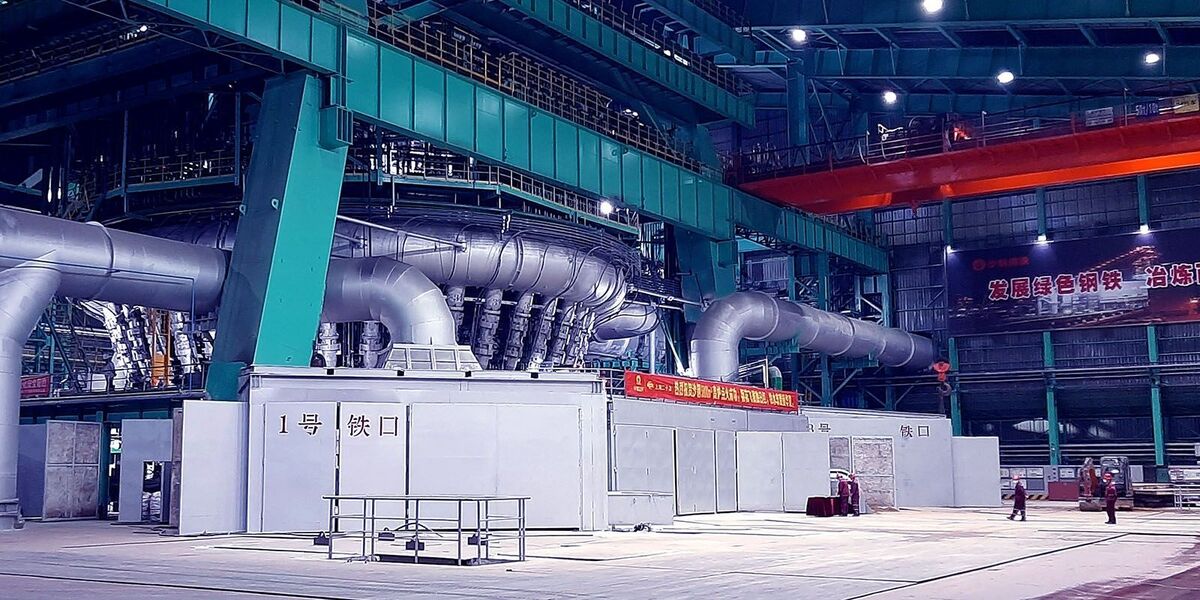

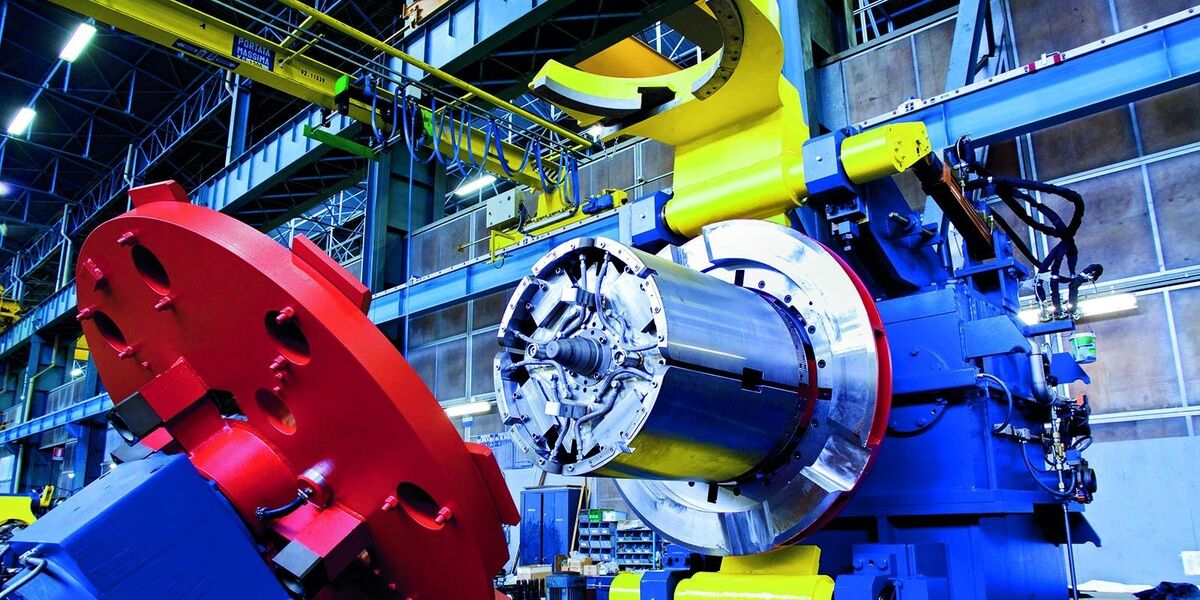

According to me-metals cited from mining.com, The new, Danieli Direct Quench DQ system Exstream II ordered by JSPL for the Steckel mill in Raigarh, India, will significantly enhance the cooling system capabilities, extending the range of achievable cooling rates and different cooling strategies in plates production.

Exstream II is the new-generation cooling system that allows easy and flexible production of a wide range of added-value products like High-Strength Steels, of plates with different mechanical properties, and lowers OpEx by reducing the amount of alloy elements in the steelmaking process for final products with improved weldability.

The DQ section of Exsteam II system is able to operate in two modes: high-pressure mode with very high cooling capability, and low-pressure mode, functioning as a normal ACC module.

The nozzle pattern ensures a uniform and effective cooling process. The headers are arranged in zones with independent control by proportional valves, allowing for the creation of a thermal profile across the plate width and ensuring precise final plate temperatures.

This installation follows a major revamping project executed by Danieli several years ago, which included major upgrades to the four-high finishing stand, pinch-roll shears, and automation system, along with new Accelerated Cooling System (ACC), power downcoiler with coil handling system, and sampling station.

All equipment will be manufactured at Danieli India quality workshops in Chennai.

source: danieli.com

Samarco gets court approval to exit bankruptcy proceedings

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Cochilco maintains copper price forecast for 2025 and 2026

Gold price stays flat following July inflation data

Mosaic to sell Brazil potash mine in $27M deal amid tariff and demand pressures

Glencore seeks $13 billion in incentives for Argentina copper projects

HSBC sees silver benefiting from gold strength, lifts forecast

Hindustan Zinc to invest $438 million to build reprocessing plant

Samarco gets court approval to exit bankruptcy proceedings

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Abcourt readies Sleeping Giant mill to pour first gold since 2014

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper