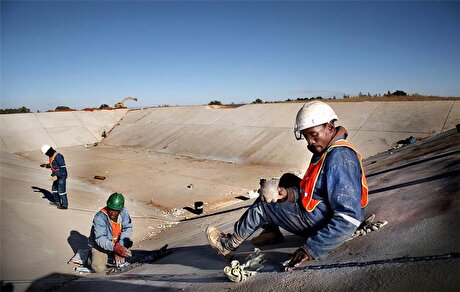

GROUNDBREAKING FOR DANIELI HYBRID MIDA MINIMILL PROJECT AT PACIFIC STEEL GROUP

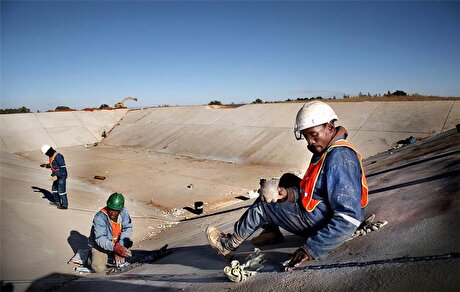

According to me-metals cited from mining.com, The engineering phase has been completed, and on-site activities were inaugurated with groundbreaking ceremony on March 5, in Mojave, California, USA, with plant commissioning scheduled for the first quarter of 2027.

Scrap will be continuously charged into Digimelter and LF digital melting and refining units, powered by the Q-One® digital power feeder which ensures the best power conditions at different frequencies.

Liquid steel will be transformed into finished products in just 10 minutes in endless casting-rolling mode assisted by Danieli Automation systems, including production intelligence, energy management and robotics for the highest efficiency, operator safety and execution repetitiveness.

“This is a very exciting day for our company. It represents a culmination of nearly 5 years of work and is the first tangible step toward full vertical integration of our reinforcing steel operations. I could not be more proud of the team that we have assembled. Their collective efforts in achieving this milestone is truly an extraordinary accomplishment,” said Pacific Steel Group CEO Eric Benson. “As we move forward with this exciting project, I am confident it will further strengthen our position as the market leader and ensure our competitiveness for many years to come.”

source: danieli.com

Uzbek gold miner said to eye $20 billion value in dual listing

Peabody–Anglo $3.8B coal deal on the brink after mine fire

A global market based on gold bars shudders on tariff threat

Minera Alamos buys Equinox’s Nevada assets for $115M

Adani’s new copper smelter in India applies to become LME-listed brand

OceanaGold hits new high on strong Q2 results

Trump says gold imports won’t be tariffed in reprieve for market

De Beers strikes first kimberlite field in 30 years

Cochilco maintains copper price forecast for 2025 and 2026

BHP shares near priciest valuation since 2021 on shift to miners

African Rainbow boosts Surge Copper stake to 19.9%

Hindustan Zinc to invest $438 million to build reprocessing plant

South Africa mining lobby gives draft law feedback with concerns

Wooden church sets off on slow Swedish road trip to escape mining subsidence

Harmony Gold’s MAC Copper takeover gets regulatory nod

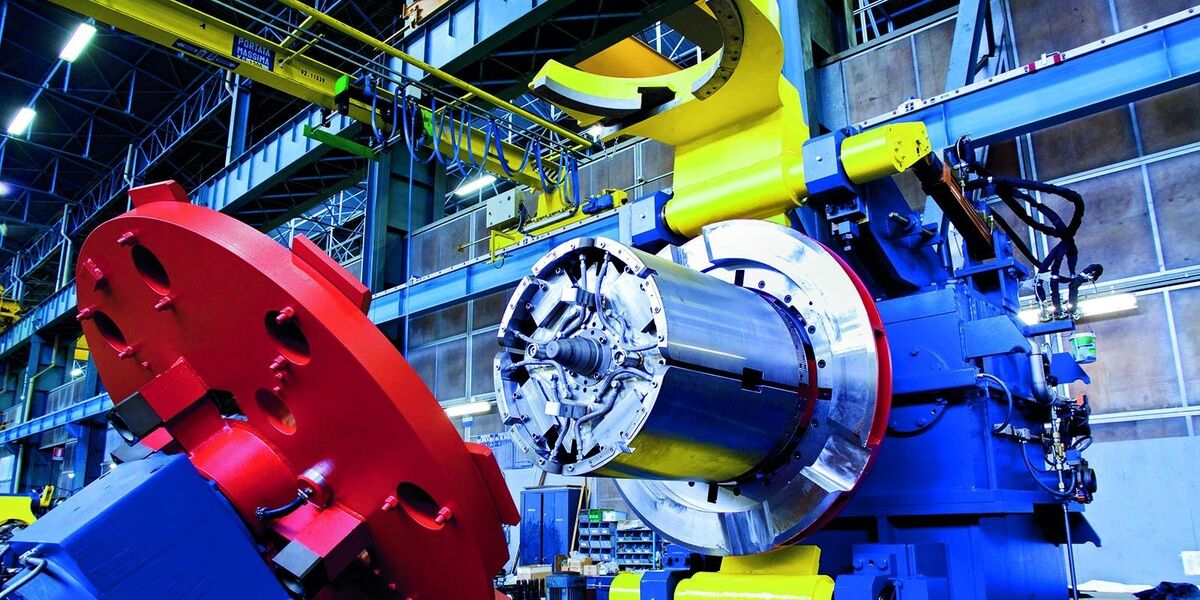

Povrly Copper Industries orders a breakdown rolling mill for high-quality copper, brass, and bronze strip production

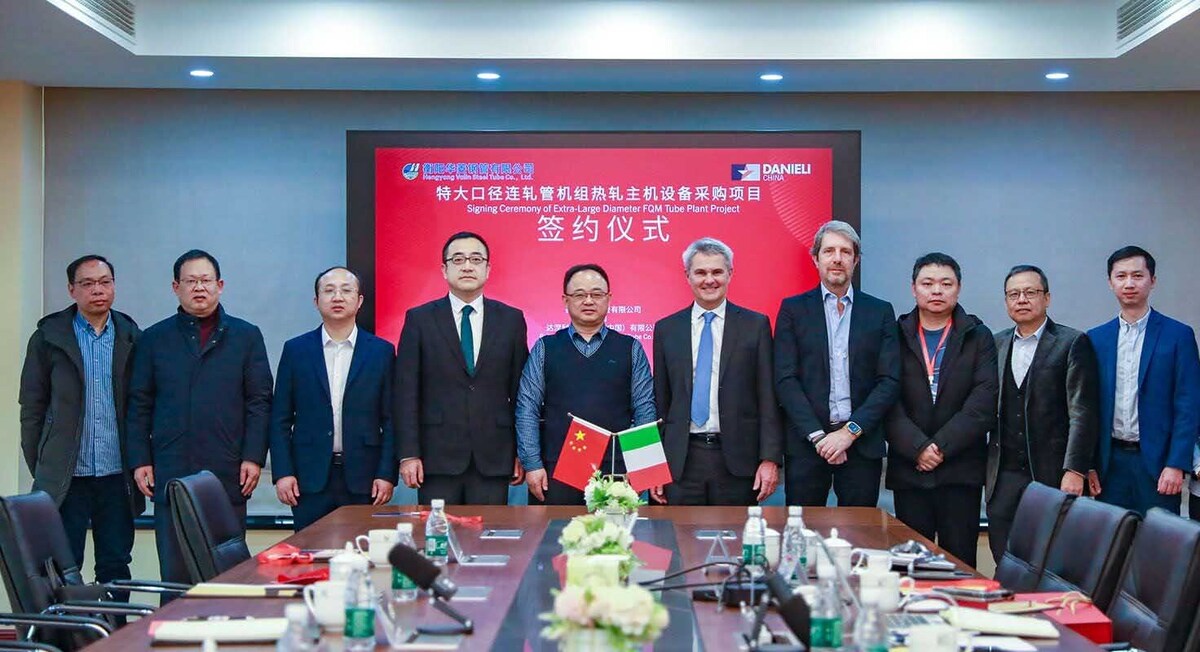

Advanced cold-rolled strip for China’s New Energy Vehicle market

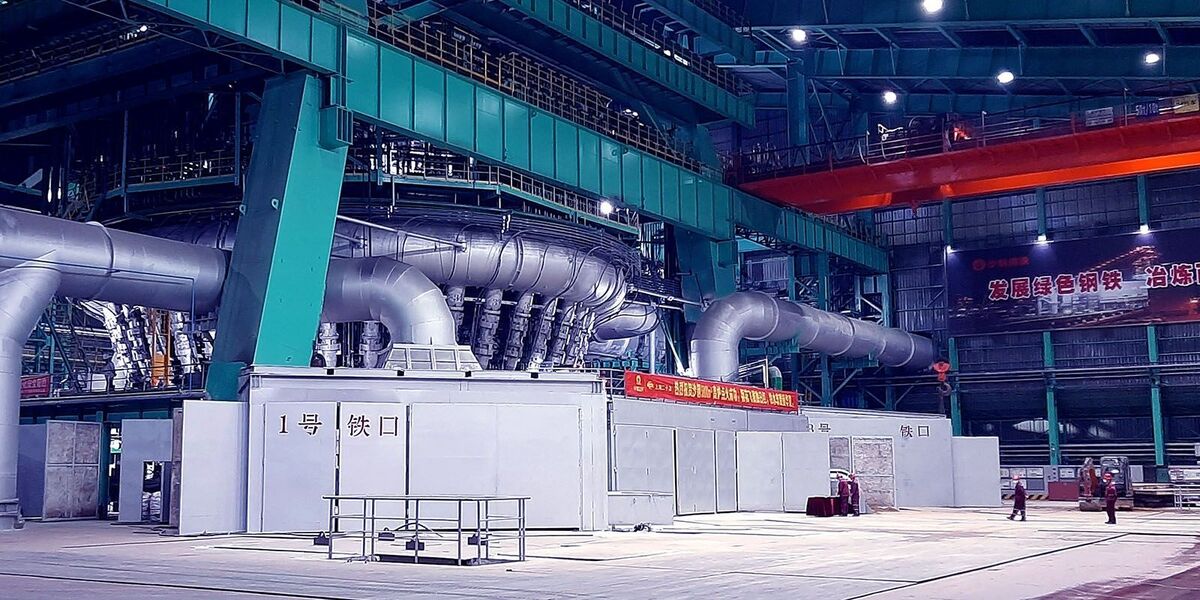

A Danieli greenfield project for competitive, quality rebar production

Antofagasta posts biggest profit margins since 2021

BHP shares near priciest valuation since 2021 on shift to miners

African Rainbow boosts Surge Copper stake to 19.9%

Hindustan Zinc to invest $438 million to build reprocessing plant

South Africa mining lobby gives draft law feedback with concerns

Wooden church sets off on slow Swedish road trip to escape mining subsidence

Harmony Gold’s MAC Copper takeover gets regulatory nod

Povrly Copper Industries orders a breakdown rolling mill for high-quality copper, brass, and bronze strip production

Advanced cold-rolled strip for China’s New Energy Vehicle market

A Danieli greenfield project for competitive, quality rebar production