ENDLESS ROLLING AND BREAKTHROUGHS ACHIEVED AT YUKUN IRON AND STEEL

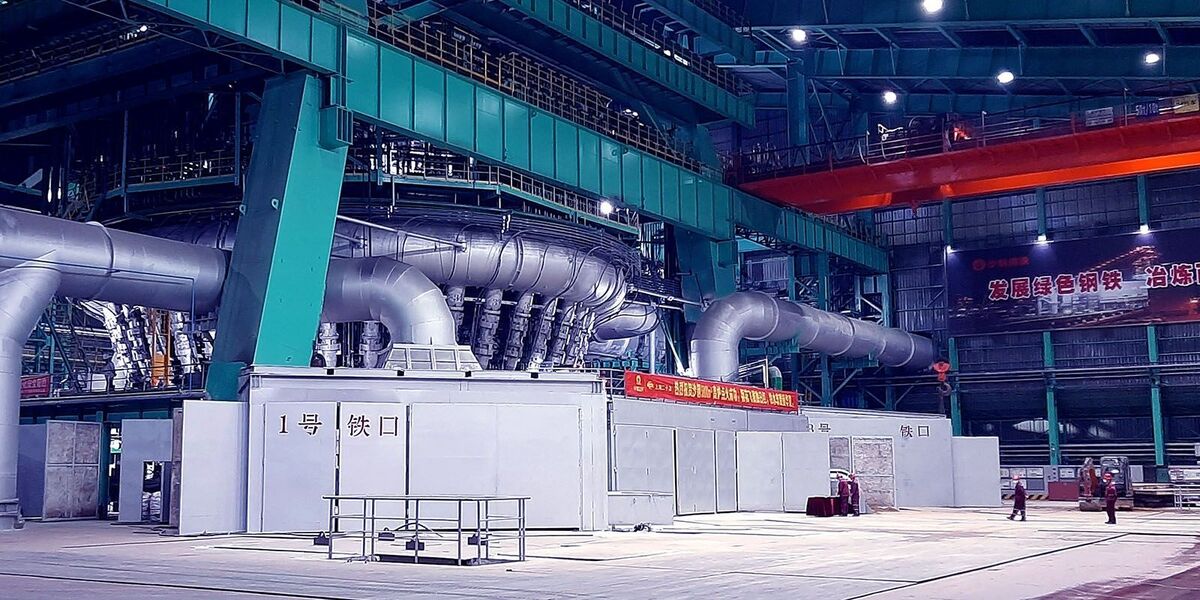

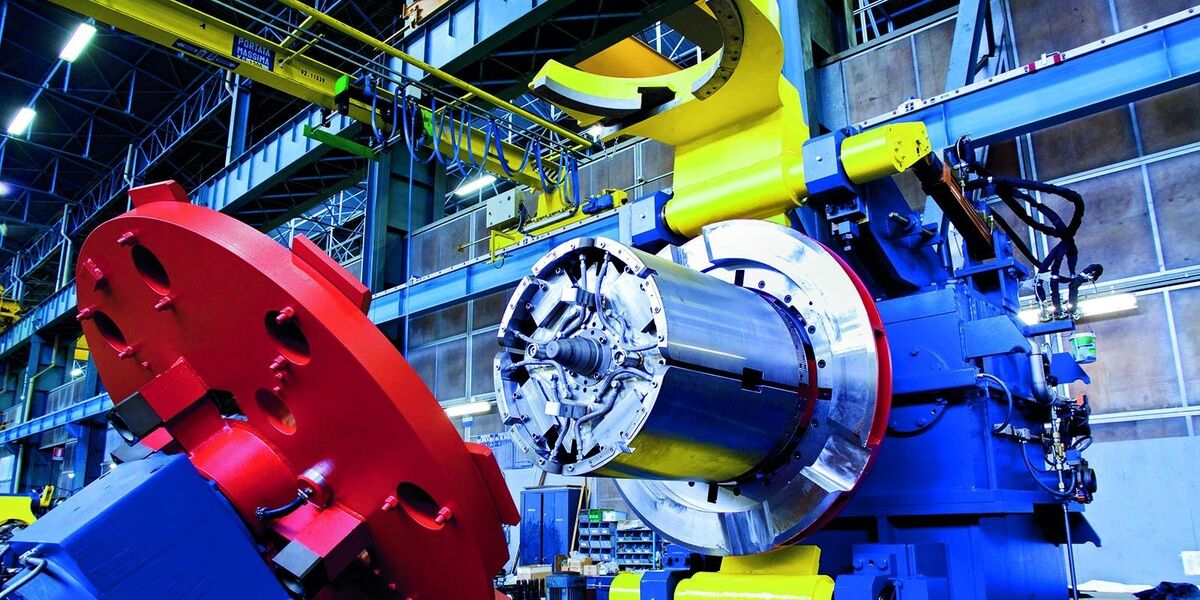

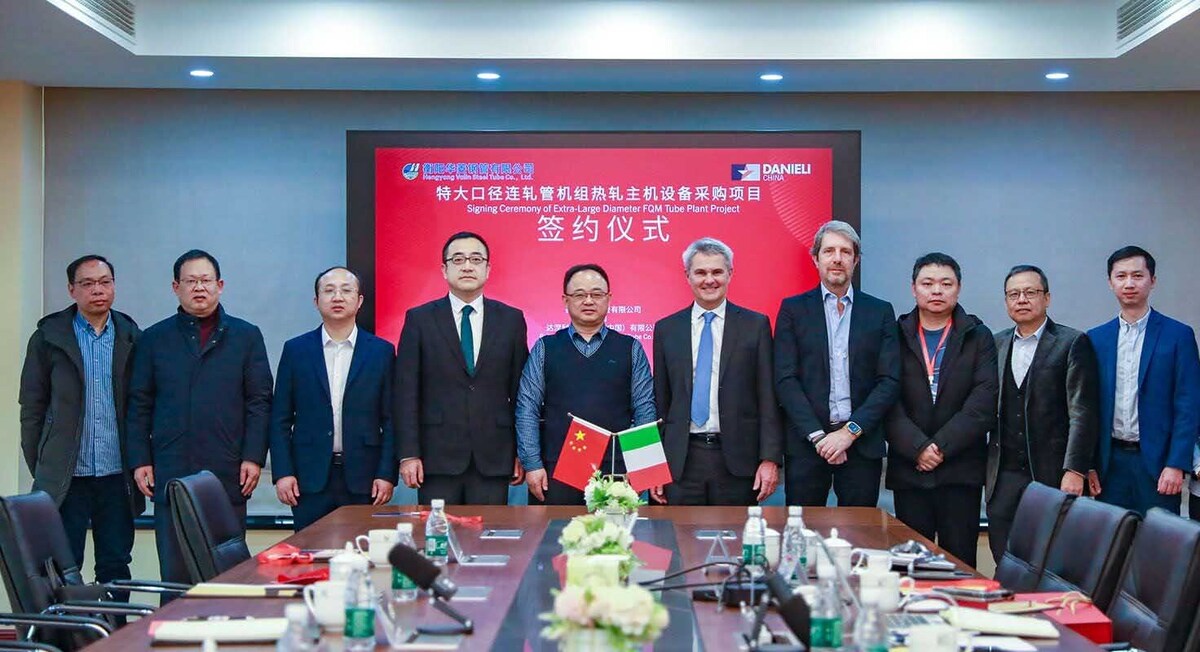

According to me-metals cited from mining.com, Operating Danieli QSP-DUE technology, Yukun is enjoying the widest production flexibility thanks to three operating modes –endless, semi-endless and coil-to-coil– which guarantee the broadest spectrum of steel grades and thicknesses.

Casting records have been set recently on the Danieli-patented DySen caster: 145-mm-thick slabs have been regularly produced –a milestone on funnel moulds.

Also, 165-mm-thick slab rolling was tested.

Endless rolling has been established, reaching the minimum design thickness of 0.8 mm thick strip within the first seven campaigns from the beginning of the endless production. Coils showed excellent surface quality, precise geometric dimensions, and uniform microstructure and properties.

This followed the production of thicknesses of 25 mm in the same line –something unique in the world.

Managed by advanced and operator-friendly Danieli Automation process controls, featuring two casting strands and endless casting-rolling on one, the QSP-DUE plant operated by Yukun has a production capacity exceeding 4.5 Mtpy of hot-rolled strip, which is the highest in the world for a direct casting-rolling plant.

The plant is designed to produce 0.8 to 25-mm-thick strip in low-carbon steel, medium-carbon steel, HSLA and medium-carbon high-alloyed grades. It incorporates more than 50 Danieli patents.

source: danieli.com

Uzbek gold miner said to eye $20 billion value in dual listing

Peabody–Anglo $3.8B coal deal on the brink after mine fire

A global market based on gold bars shudders on tariff threat

Minera Alamos buys Equinox’s Nevada assets for $115M

Adani’s new copper smelter in India applies to become LME-listed brand

OceanaGold hits new high on strong Q2 results

Trump says gold imports won’t be tariffed in reprieve for market

De Beers strikes first kimberlite field in 30 years

Cochilco maintains copper price forecast for 2025 and 2026

BHP shares near priciest valuation since 2021 on shift to miners

African Rainbow boosts Surge Copper stake to 19.9%

Hindustan Zinc to invest $438 million to build reprocessing plant

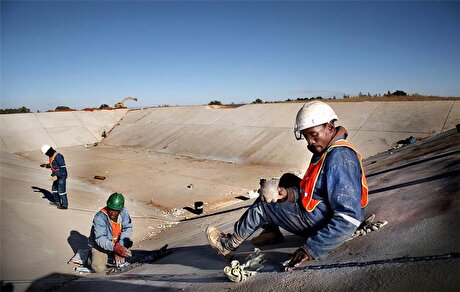

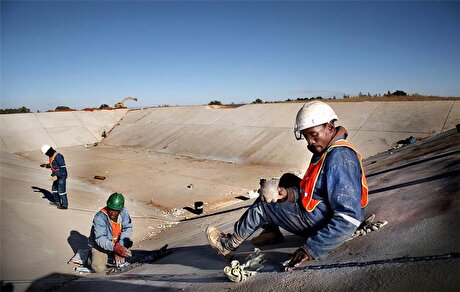

South Africa mining lobby gives draft law feedback with concerns

Wooden church sets off on slow Swedish road trip to escape mining subsidence

Harmony Gold’s MAC Copper takeover gets regulatory nod

Povrly Copper Industries orders a breakdown rolling mill for high-quality copper, brass, and bronze strip production

Advanced cold-rolled strip for China’s New Energy Vehicle market

A Danieli greenfield project for competitive, quality rebar production

Antofagasta posts biggest profit margins since 2021

BHP shares near priciest valuation since 2021 on shift to miners

African Rainbow boosts Surge Copper stake to 19.9%

Hindustan Zinc to invest $438 million to build reprocessing plant

South Africa mining lobby gives draft law feedback with concerns

Wooden church sets off on slow Swedish road trip to escape mining subsidence

Harmony Gold’s MAC Copper takeover gets regulatory nod

Povrly Copper Industries orders a breakdown rolling mill for high-quality copper, brass, and bronze strip production

Advanced cold-rolled strip for China’s New Energy Vehicle market

A Danieli greenfield project for competitive, quality rebar production