Three Danieli Corus startups in converter steelmaking

This new 180 t converter is equipped with the patented suspension system based on a vertical Lamella arrangement in combination with horizontal Daniella elements, an air cooling system for the barrel part of the vessel and water–based cooling for the vessel’s top cone. A Q–Temp 2.0 temperature monitoring system was installed for online measurement of the vessel’s thermal condition, providing valuable information for achieving the longest possible campaigns.

ArcelorMittal Temirtau Converter No. 3

With a first heat produced on 20th February 2021, ArcelorMittal has successfully completed the commissioning of their new 300 t Converter No. 3, which was supplied by Danieli Corus. The converter vessel, trunnion ring, suspension, couplings as well as other ancillary equipment have been designed and manufactured for a lifetime of 30 years. With an improved design, the inner volume was increased, in turn optimizing the reaction volume. Clearance between the vessel shell and trunnion ring was increased for improved cooling characteristics and as such increase lifetime of the vessel shell.

Hegang Laoting Sublance System for Converter No. 1 in BOF Shop 2

On Wednesday May 26th, the First Heat of Converter No. 1 at Hegang Laoting BOF Shop 2 was executed, and the first two Sublance measurements were completed successfully. This is the third Sublance System to be put successfully into production at this steel plant, allowing the client to produce heats with these converters in full computer mode thanks to the Static–Dynamic Level II Process Model that was also implemented.

Source: Danieli

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

UBS lifts 2026 gold forecasts on US macro risks

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

Afghanistan says China seeks its participation in Belt and Road Initiative

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

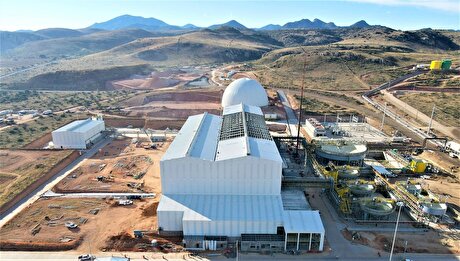

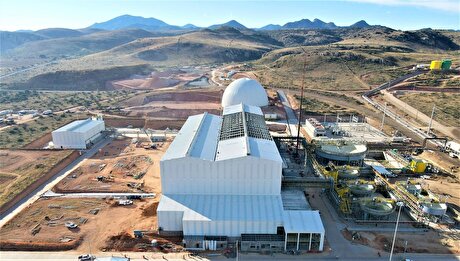

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery