Glencore ties up with Cyclic Materials in copper recycling push

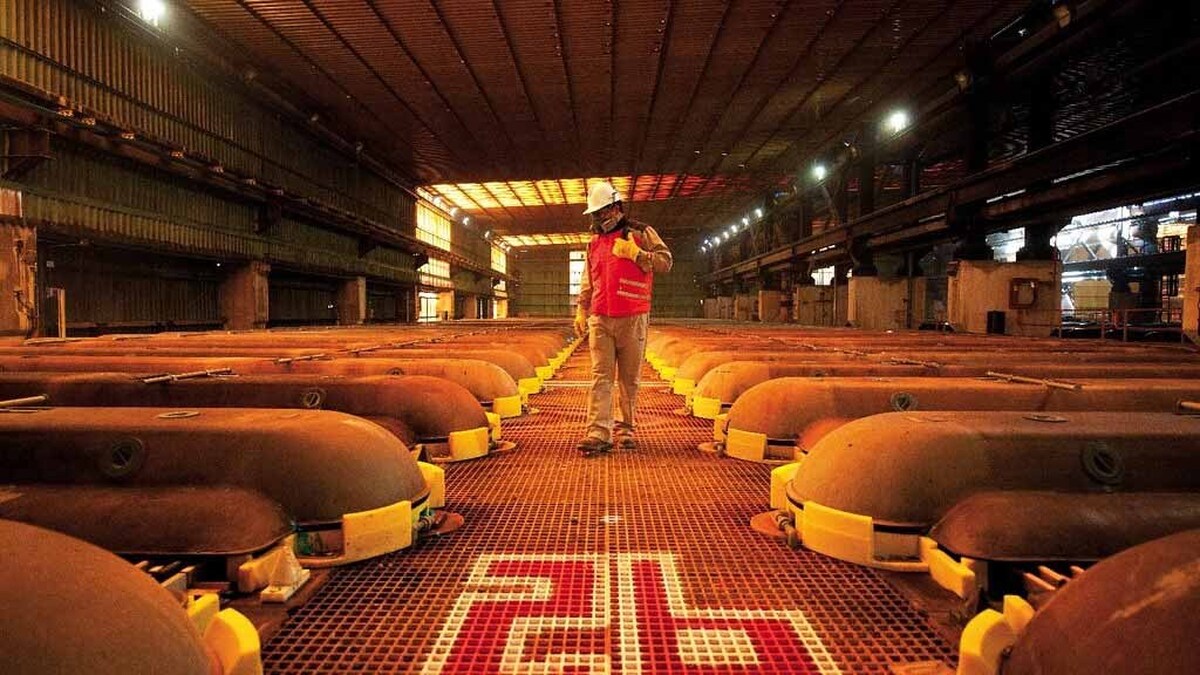

According to me-metals cited from mining.com, As part of a multi-year agreement, Cyclic Materials will sell copper scrap to Glencore, which will process and refine the metal at its Horne smelter and Copper Refinery in Quebec to turn it into copper cathodes. The Horne smelter is North America’s largest recycler of copper and precious metals, according to Glencore.

Ahmad Ghahreman, co-founder and CEO of Cyclic Materials told Reuters that reducing the carbon footprint of copper and reusing metals are an important conversation among mining companies.

The call for copper is poised to surge in coming years due to its role in electric vehicles, renewable energy and data centers for artificial intelligence.

Demand is expected to outstrip supply by 1.7% in 2035, and copper prices have scaled to record highs this year. It takes at least 10 years and as much as $5 billion to build a copper mine from scratch. Even if companies do build mines there are other challenges with social capital as seen with opposition to mining by local communities from Panama to Serbia.

Cyclic Materials, which recycles rare earths and copper from end-of-life electric vehicle motors, wind turbines, MRI machines, and data center electronic scrap, is expected to start delivery by the end of 2025.

Though the financial deals of the agreement are still confidential, Ghahreman said they have benchmarked to the price of high grade scrap copper which is at a small discount to the LME copper price.

Three-month copper on the London Metal Exchange is currently trading just above $9,200 per metric ton.

Kunal Sinha, global head of recycling at Glencore, said in a statement this partnership broadens the scope for the company’s recycling activities in this field as it will receive copper materials from additional sources.

source: mining.com

Uzbek gold miner said to eye $20 billion value in dual listing

Peabody–Anglo $3.8B coal deal on the brink after mine fire

Minera Alamos buys Equinox’s Nevada assets for $115M

OceanaGold hits new high on strong Q2 results

Adani’s new copper smelter in India applies to become LME-listed brand

Cochilco maintains copper price forecast for 2025 and 2026

Trump says gold imports won’t be tariffed in reprieve for market

Discovery Silver hits new high on first quarterly results as producer

De Beers strikes first kimberlite field in 30 years

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects

Iron ore price falls with BHP results, soft China demand in focus

UBS lifts 2026 gold forecasts on US macro risks

BHP shares near priciest valuation since 2021 on shift to miners

African Rainbow boosts Surge Copper stake to 19.9%

Hindustan Zinc to invest $438 million to build reprocessing plant

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects

Iron ore price falls with BHP results, soft China demand in focus

UBS lifts 2026 gold forecasts on US macro risks

BHP shares near priciest valuation since 2021 on shift to miners

African Rainbow boosts Surge Copper stake to 19.9%