Gold, silver and platinum now printed directly onto fabrics

Up till now, metals were printed onto fabrics by coating them with plastic. The new approach, however, allows metal inks to cover entire fibres rather than simply coating the surface of the fabric.

In a media brief, the researchers explained that to coat the fibres, they first covered them in microscopic particles of silicon, and then submerged the material into a solution containing metal ions. The process, known as SIAM or Si ink-enabled autocatalytic metallization, allowed the metals to spread throughout the material as the ions were deposited on the silicon particles.

Since the metal coats the entire fabric, it allows it to maintain its ability to absorb water and it's flexibility.

To prove the technique, the team lead by bioengineer Firat Güder tried different things, among them the creation of silver coil antennas on paper, which can be used for data and power transmission in wireless devices such as Oyster cards and contactless payment systems. They also used the method to deposit silver onto paper and then added zinc onto the same paper to form a battery.

In other words, they say the technique could be used to ultimately incorporate batteries, wireless technologies and sensors into things such as paper and cotton textiles.

“The beauty of this approach is that it can also combine different technologies to serve a more complex application, for example low-cost sensors can be printed on paper that can then transmit the data they collect through contactless technology. This could be particularly useful in the developing world where diagnostic tests need to be conducted at the point of care, in remote locations and cheaply," said researcher Max Grell, who published the team's findings in an article published in the journal Advanced Functional Materials.

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

UBS lifts 2026 gold forecasts on US macro risks

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

EverMetal launches US-based critical metals recycling platform

Afghanistan says China seeks its participation in Belt and Road Initiative

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

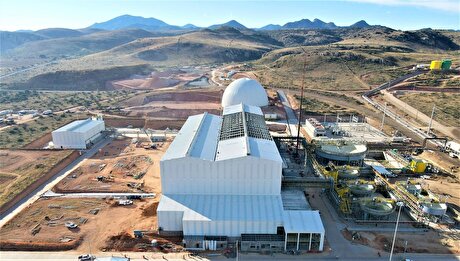

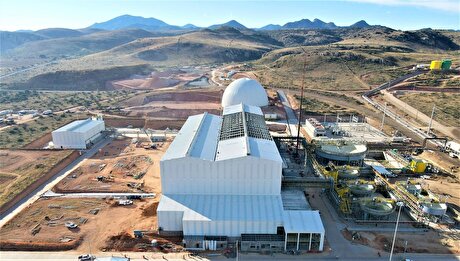

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery