The transportation system in Mobarakeh steel was made smart/ 3 more projects are under design

According to Me-Metals, Hamed Arabi, the manager of the three IRISA company's digital transformation projects that were implemented in Mobarakeh Steel Company, stated: One of the most important matters in the field of technical services and support in Mobarakeh Steel Company is the topic of transportation and logistics; Every day, a large number of different transportation mechanisms, both inside and outside the company, carry out the process of moving materials and goods, equipment, products, and human resources.

He added: A significant part of the company's expenses is spent on transporting goods and moving personnel. It is obvious that optimal use of available resources and proper management of their use has always been one of the concerns of management; On the other hand, in recent years, the issue of fleet management in the field of transportation through intelligent systems has been the focus of organizations and many solutions have been presented for it.

The project manager of Irisa Company stated: Therefore, after unveiling the digital transformation plan of Mobarakeh Steel Company and defining the areas of improvement, the subject of transportation and logistics is one of the company's priorities for optimization through the use of new technologies and smart identification tools and smart logistics projects. In the form of an integrated plan, it was put on the agenda of Mobarakeh's digital transformation plan.

He clarified: Considering the number and scope of the beneficiaries of this issue, the smart logistics platform was divided into 6 different sections and each section was defined as a separate project by observing the principle of integration between them in order to meet the multiple needs of the beneficiaries.

Arabi by stating that the intelligent management of the movement of personnel - heavy transportation, the intelligent management of movement of personnel - light transportation, the monitoring of the transportation status of internal industrial mechanisms, the monitoring of the transportation status of steelmaking slag, the monitoring of the transportation status of materials and rail products, and the monitoring of the transportation status of materials and The road product is one of the titles of these projects, he said: 3 projects have been operated in Mobarakeh Steel out of these 6 projects and 3 other projects are being developed.

He stated that regarding the project of intelligent management of personnel movement - heavy transport: one of the most important parts of logistics is the management of personnel's daily movement to and from the workplace and vice versa, which is carried out by the heavy transport fleet of Mobarakeh Steel in a wide area between cities The accommodation of the personnel is done at Mobarakeh Steel. This project was defined with the aim of increasing the satisfaction and quality level of services, increasing the safety level of the fleet, reducing management costs and finally increasing the efficiency of the fleet.

The project manager of Irisa company stated that in general, the process of moving personnel by the heavy fleet can be divided into three parts: before the trip with the perspective of planning, during the trip with the point of view of real-time control and monitoring, and the end of the trip with the view of analyzing the trips that happened. He continued: Mobarakeh steel's heavy transport fleet is permanently and daily three times in charge of providing transportation services to personnel. With the aim of managing the fleet in the covered area in three provinces, the maximum use of the existing fleet's ability was one of the important goals in defining this project.

He stated: In this project, by providing various user interfaces, information such as the current status of the fleet is displayed by monitoring the position, traffic route, distance traveled, speed at the moment and management of all types of routes, stations and fleet. Also, by using the data processing received from the equipment installed in the fleet, vehicle movement status monitoring, driver behavior monitoring, vehicle status types, and personnel entry and exit monitoring are done. The use of this system provides the possibility of real-time control of fleet traffic, and by collecting and analyzing accurate statistics on the use of fleet capacities, it enables the optimal allocation of the fleet to stations, the optimal definition of routes, etc.

Arabi also said about the smart transportation management project of personnel - light transportation: the smart transportation management system of Princel (light transportation) has provided a comprehensive and integrated solution to respond to transfer requests by the light transportation fleet for Mobarakeh steel personnel. In such a way that personnel requests are sent to the light transportation unit after registering in the personnel mobile application and receiving confirmations in the organizational hierarchy, and if there are available resources, they are converted into one or more trips.

He continued: This trip is communicated to the relevant driver through the driver application and all the stages of the trip are also monitored in it. By means of this system, all information, including the start and end time of the trip, the distance traveled, the performance of the drivers, the current position of the cars, etc., are collected and analyzed. This system with the ability to be installed on a mobile phone, with features such as registering a travel request by personnel, assigning a car, making a trip by a driver, surveying and other facilities, trying to create ease for users, speed in responding to requests, optimal use of car capacity. , has reduced transportation costs and increased the level of staff satisfaction.

The project manager of Irisa Company stated: Other goals of the implementation of this system are to improve the performance status of the employees' transportation fleet through the intelligent system and evaluate the performance of subordinate units, improve processes, as well as facilitate planning and continuity of services in various situations, especially emergency situations with cost. It is reasonable.

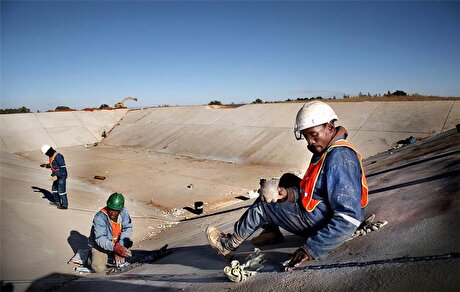

Regarding the project of monitoring the state of domestic industrial mechanisms transport, he also expressed: due to the size of Mobarakeh Steel Company and the large distances between different units, the system for monitoring the state of domestic industrial mechanisms has been created with the aim of creating unity in the control of internal transport. Another goal of this system is to increase the ability to manage and direct transport requests, as well as make appropriate decisions to improve the efficiency of transport mechanisms inside the fence.

Arabi said: Using the information of drivers and the relevant fleet, this system receives transport requests from the production areas known as system operators, and after processing, the desired mechanism is selected, taking into account parameters such as the location of the existing mechanisms. The expected time for providing the service from the districts, the estimated duration of the service, the state of the mechanisms and their level of readiness, etc., are assigned to the operator.

He added: The use of this system helps managers to provide the highest level of services with the desired quality and at the right time, to optimally use the available capacities and significantly reduce the costs of operation and maintenance of the mechanisms and increase the efficiency of the process. give Also, by analyzing the routine and common requests of the areas at specific times, it is possible for managers to plan optimally for the allocation of mechanisms and to predict future requests.

Irisa project manager pointed out that in addition to the above projects, three other projects are being designed to complete the smart logistics platform of Mobarakeh Steel, which we will witness their operation in the near future. It was done with the participation of Irancell and Basir Remote Sensing companies and using domestic power and local products, and it can be used as a model for other industries in the country to improve productivity in the field of transportation.

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Roshel, Swebor partner to produce ballistic-grade steel in Canada

Iron ore price dips on China blast furnace cuts, US trade restrictions

Emirates Global Aluminium unit to exit Guinea after mine seized

South Africa mining lobby gives draft law feedback with concerns

EverMetal launches US-based critical metals recycling platform

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study