Iranian Scientists Find Low-Cost Method to Produce Gasoline, Petrochemical Products

The use of oil in production of catalysts is highly expensive, and in this project we used natural gas and converted the gas into light olefins by MTO method,” Eshaq Moradian, one of the researchers, said.

“Also, in this project, we used ultrasonic waves in the catalytic design and fabrication stage as well as the nano properties of the materials to reduce the fabrication reaction time and decrease the conventional refinery costs,” he added.

Moradian underlined that the project is ready for exercise at petrochemical industries and gasoline refineries.

In a relevant development in 2018, Iranian researchers at Kermanshah oil refinery could produce different types of catalysts to be injected into the petroleum sludge, making the country as the only producer of the product in the world.

Petroleum sludge is a complex mixture containing different quantities of waste oil, waste water, sand and mineral matter.

Petroleum industries are responsible for the generation of large quantities of sludge, which is a major source of environmental pollution.

Injection of the low-price catalysts, produced in Kermanshah refinery in Western Iran, into the petroleum sludge decreases the environmental pollution, turns oil wastes into valuable products and reduces the time needed for building installations and implementing projects.

Oil sludge, an inevitable by-product, is generated wherever exploitation, transportation and refining occurs in petroleum industry. It is a complex mixture of petroleum hydrocarbons and water with solid mineral admixture.

Both the oil field sludge and the oil tank sludge comprise abundant of toxic substances from the most carcinogenic polycyclic aromatic to heavy metal, and even to radioactive material. Most of them pose the potential risks for human health and the environment.

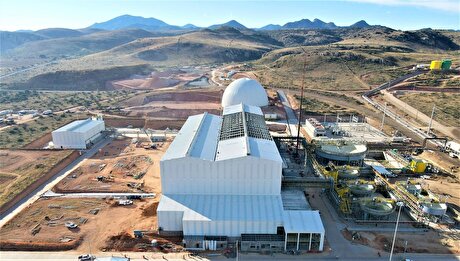

Barrick’s Reko Diq in line for $410M ADB backing

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Pan American locks in $2.1B takeover of MAG Silver

US adds copper, potash, silicon in critical minerals list shake-up

Gold price gains 1% as Powell gives dovish signal

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

Gold boom drives rising costs for Aussie producers

US seeks to stockpile cobalt for first time in decades

Giustra-backed mining firm teams up with informal miners in Colombia

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook