Ternium Argentina awards SMS group FAC for successful upgrade of gas cleaning plants

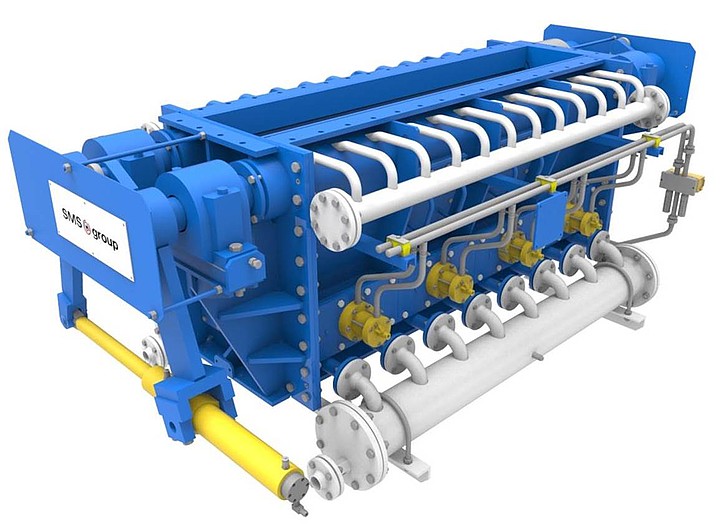

The venturi throat from SMS group helps to reduce emissions significantly.

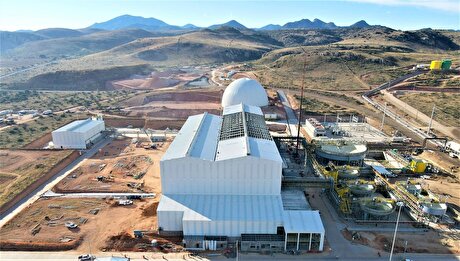

As part of a planned increase in the production capacity of the three 190-ton converters, the gas cleaning plants, installed in the 1970s, were upgraded to the state of the art and now provide far more efficient cleaning results. Offgas emissions were reduced to below 25 mg/Nm³; the legal limit is 50 mg/Nm³.

Cesar Alejandro Parisi, Ternium Argentina, Head of Plant Development Department for Hot Rolling Mill and Steelplant:

“This upgrade of our gas cleaning plants means we are ideally equipped to meet the environmental challenges of the future. The performance of SMS group’s environmental technology comes up to and even exceeds our expectations.”

For the revamp of the three scrubbers, SMS group supplied key components as well as two main induced-draft fans for gas cleaning. The venturi throat, developed by SMS group, features a new type of nozzle geometry and arrangement, which ensures extraction of a larger quantity of dust particles.

The scope of supply also included the measuring technology for the venturi scrubber and the whole gas cleaning plant, including the cooling stack, as well as the supervision of the erection work and commissioning.

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

UBS lifts 2026 gold forecasts on US macro risks

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

Afghanistan says China seeks its participation in Belt and Road Initiative

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery