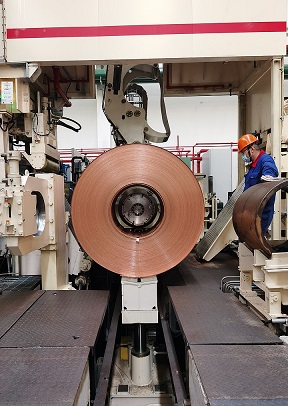

Second copper cold rolling mill from sms group started operation at jintian ningbo copper

The plant is designed for intermediate and finish rolling of cold strip made of copper and copper alloys. The success is linked seamlessly and quickly to the start of production of the breakdown mill in mid-March 2020. With this, Jintian Ningbo Copper Co., Ltd. has increased the production capacity by further process levels.

Intermediate and finish rolling is carried out by the new reversing cold mill in CVC®plus six-high design. The maximum strip width is 650 millimeters with a maximum ingoing thickness of up to 3 millimeters. The minimum strip thickness that can be achieved with this rolling stage is 0.1 millimeters as a final product or as semi-finished product for further processing.

The six-high cold rolling mill is provided with the latest rolling technology, which offers maximum flexibility in production planning and ensures excellent quality for the rolled products. Beside the hydraulic adjustment system, the proven CVC®plus technology (Continuous Variable Crown) for the precise setting of the roll gap is applied. Work roll shifting combined with the positive and negative work and intermediate roll bending ensures precise and economically efficient rolling operation. The exit side multizone cooling system finalizes the flatness results at high level.

The X-Pact® electrical and automation system from SMS group performs rolling process control and monitoring. Among other things, it includes Level 2 which is perfectly matched to the plant type and the product portfolio.

SMS group also supplied the fluid power systems. A Multi-Plate® filter ensures sustainable cleaning of the rolling oil.

The next important milestone will be reached in mid-May; the third cold rolling mill is scheduled to go into operation at that time. Jintian Ningbo Copper Co., Ltd. is already very satisfied with the performance of SMS group, which was delivered in a particularly challenging time.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook