Dan'roll technologies for steel and Aluminium strip processing

Two recent cases in Europe show flexible projects execution meeting customers’ specific niche requests.

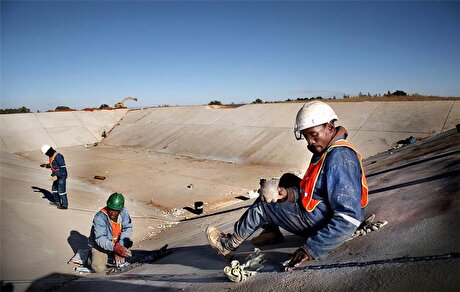

A series of sink rolls designed and manufactured for a hot-dip galvanizing line has been commissioned at a plant in Poland.

The supplied sink-rolls were made of high corrosion-resistant, ferrite-free AISI 316L stainless steel, cast using high-technology centrifugal processes to improve overall campaign life and reliability as compared to the original rolls. Finished strip quality was improved thanks to specially shaped ducts along the length of the roll for better zinc distribution.

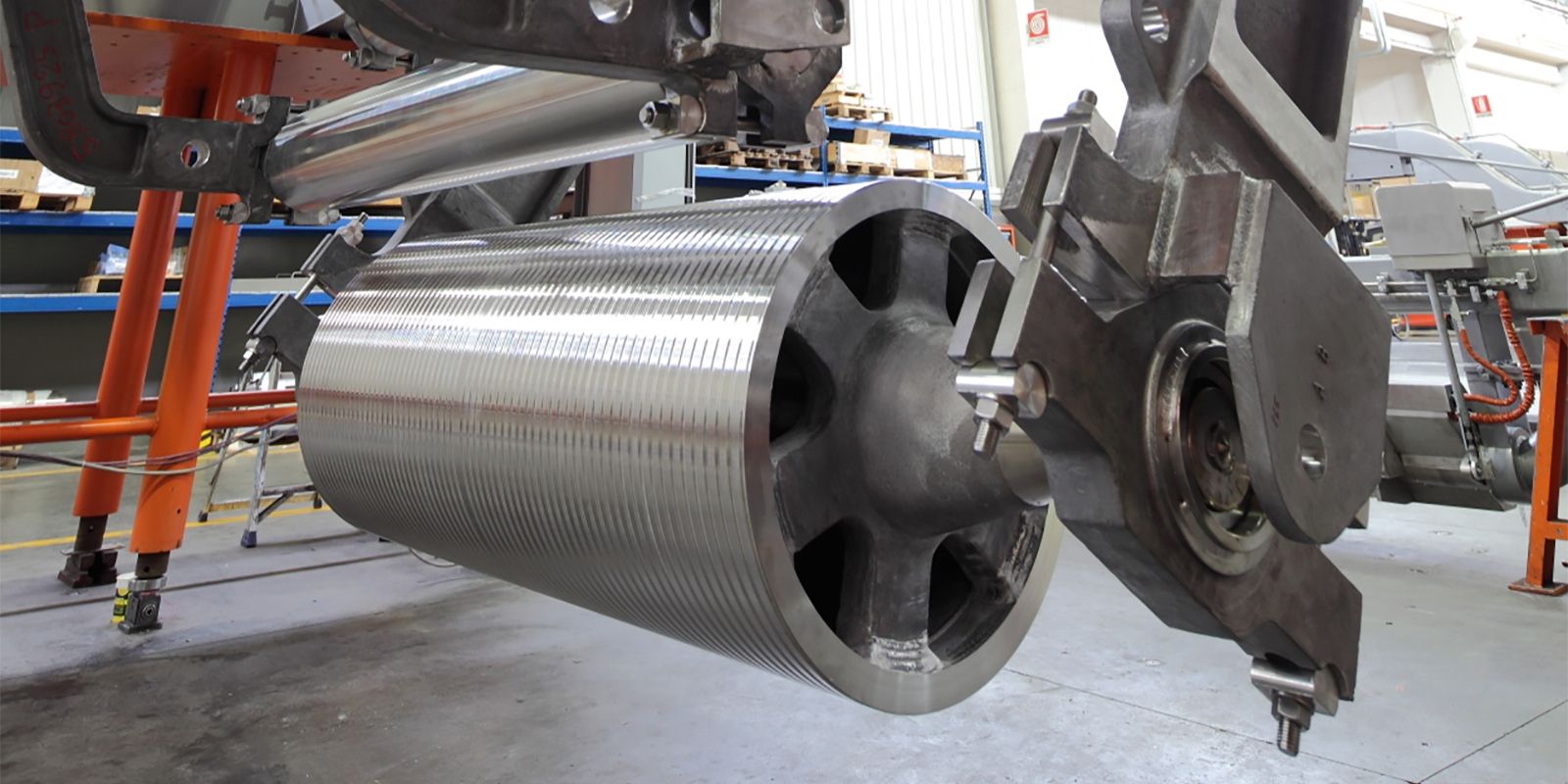

A complete set of precision, high-quality work rolls for an aluminum cold-leveler also has been supplied for another producer, in Serbia.

The purpose of this order was to replace worn rolls with new high-tech rolls capable to guarantee the best quality strip finishing. The rolls have been engineered and manufactured utilizing an in-house, induction hardening heat-treating process. As a result, the final roll finishing tolerances of 0.005 mm cylindricity and concentricity over the machined roll barrel have been delivered by the supplied Dan’Roll products.

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Emirates Global Aluminium unit to exit Guinea after mine seized

Roshel, Swebor partner to produce ballistic-grade steel in Canada

Iron ore price dips on China blast furnace cuts, US trade restrictions

South Africa mining lobby gives draft law feedback with concerns

EverMetal launches US-based critical metals recycling platform

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study