Aluminium replaces Copper: Talga and Bentley Motors to develop graphene-enhanced motor parts

The OCTOPUS project aims to deliver the ultimate single unit e-axle solution designed specifically to meet Bentley Motors' performance specifications via optimized motor and power electronics technology and materials. The project is funded under the Office for Low Emission Vehicles’ and Innovate UK’s “IDP15: The Road to Zero-Emission Vehicles” competition.

Under the project Talga will develop and provide graphene materials for the high-performance electric motor windings to deliver an aluminium-based solution aimed at outperforming, and ultimately replacing, the copper windings currently used.

The improved motor windings form part of the project’s aim of developing next-generation lightweight high-performance component systems that integrate the latest advanced materials and manufacturing techniques.

The components are to be tested at the sub-system and system level for an integration route into future e-axle designs.

Mark Thompson, Talga Managing Director: “We are delighted to engage in jointly developing Bentley Motors’ e-axle concept with our consortium partners and are honoured to have earned Innovate UK’s continued support. The successful use of Talga graphene material to lend aluminium the properties required to outperform copper in electric motors would be a big advancement. For automotive manufacturers, this could reduce vehicle weight and increase performance, safety, and driving range while retaining sustainability and economics. Lightweight and high-performance automotive components perfectly complement our Li-ion battery anode products, and the advancement could pave the way for opportunities to replace copper wire in many large-scale applications globally.”

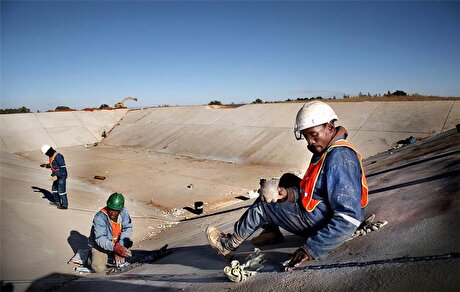

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Emirates Global Aluminium unit to exit Guinea after mine seized

Roshel, Swebor partner to produce ballistic-grade steel in Canada

Iron ore price dips on China blast furnace cuts, US trade restrictions

South Africa mining lobby gives draft law feedback with concerns

EverMetal launches US-based critical metals recycling platform

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study