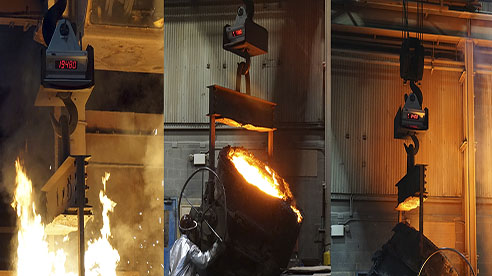

EHP: Energy saving with weighing technology

Foundries in particular have immense potential to benefit from the diverse “IoT” opportunities of the future. In our industry, fast processes, strict monitoring of product development and avoidance of work hazards when dealing with hot material are important.

The crane scale and load cell manufacturer EHP Wägetechnik from Buehl in Germany is now taking the next step into this future in order to make its customers' processes “smarter”.

For decades, the company has been offering weighing solutions especially for foundries, such as a heat-protected crane scale that can be used to weigh material that is up to 1,600 ° C and to transport it safely. The innovative product portfolio also includes wireless transmission of the weighing data to different receiving units.

The intelligent crane scale communicates with the other machines in the foundry

"We are currently developing an intelligent crane scale in close cooperation with crane manufacturers and our long-standing customers, which can also communicate with other machines in the foundry," says company owner Albert Friedmann.

This opens up an unprecedented number of innovation opportunities for the customer: "EHP crane scales will be used in the future control the filling volume of the melting crucibles independently or dose the feedstocks more efficiently when classifying them, ”explains Technical Director Markus Ebel.

The energy saving that results from the optimization of the foundry processes is also one of the declared goals of the Baden company.

Rethinking safety

"Safety aspects can be rethought, since no worker has to act in the immediate vicinity in the case of dangerous casting processes," emphasizes Development Manager Timo Oberle.

This means that the crane scale becomes the central starting point for successively optimizing processes, making them safer and more efficient. Each foundry can then individually determine which processes they want to automate and in what level of detail.

EHP Weighing Technology is looking for a non-binding exchange with foundries and industrial companies that are thinking about automating their weighing processes in order to clarify individual requirements here. Get in touch by email at info(at)ehp.de and ask your questions.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook