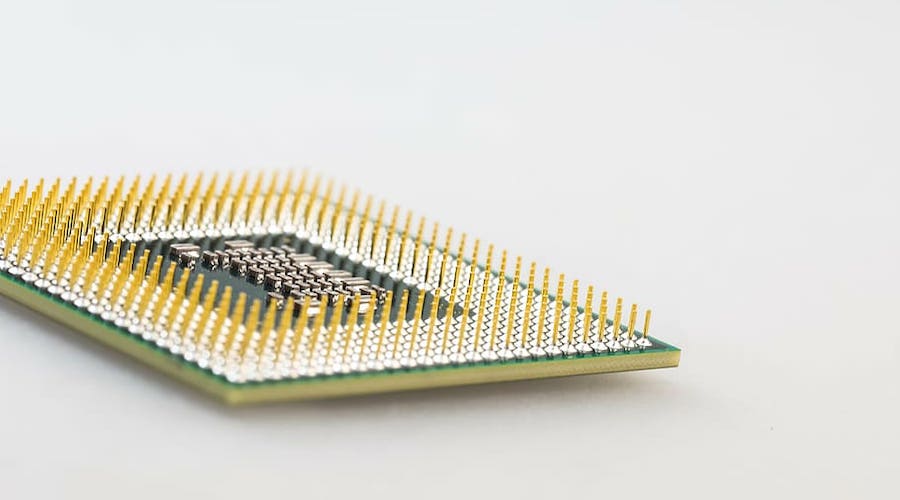

Tiny electronics can still rely on gold

The study was carried out because engineers were starting to worry about the possibility of the tiny gold wires that are used in electronics behaving more like a liquid than a solid as circuits shrink to the nanoscale.

To run this experiment, the researchers figured out how to pressurize gold particles just 4 nanometers in length — the smallest particles ever measured

Thus, a research team at Stanford University, Korea Advanced Institute of Science and Technology and Trinity College conducted an experiment in which they used a device known as a diamond anvil cell, normally employed to compress gold. The idea was to put tiny gold particles under extreme pressure, while simultaneously measuring how much that pressure damaged gold’s atomic structure.

The anvil’s pressure dislodged some atoms from the crystal and created tiny defects in the gold. According to the study’s lead scientist, Wendy Gu, such a reaction was expected because a nanoparticle of gold is built like a skyscraper with atoms forming a crystalline lattice of neat rows and columns.

Since the gold particles were only four nanometers in length, to detect the defects Gu and her team shined X-rays through the diamond onto the gold. Defects in the crystal caused the X-rays to reflect at different angles than they would on uncompressed gold.

By measuring variations in the angles at which the X-rays bounced off the particles before and after pressure was applied, the team was able to tell whether the particles retained the deformations or reverted to their original state when pressure was lifted.

“The defects remain after pressure was removed, which told us that gold behaves like a solid even at such scales,” Gu said in a media statement. “For the foreseeable future, gold’s luster will not fade.”

In summary, the findings mean that chipmakers can know with certainty that they’ll be able to design stable nanodevices using gold for years to come.

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Gold Fields nears $2.4B Gold Road takeover ahead of vote

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Cleveland-Cliffs inks multiyear steel pacts with US automakers in tariff aftershock

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Tailings could meet much of US critical mineral demand – study

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Glencore targets 1Mt of copper in Argentina over coming decade

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Glencore targets 1Mt of copper in Argentina over coming decade

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

Abcourt readies Sleeping Giant mill to pour first gold since 2014