NUCOR-JFE STEEL Mexico Orders a Hot-Dip Galvanizing Line and Recoiling Line from SMS Group

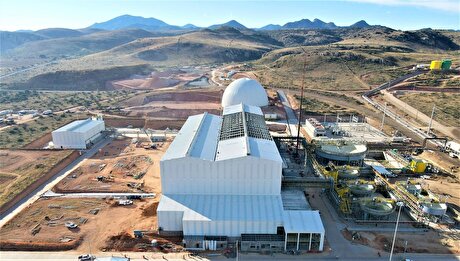

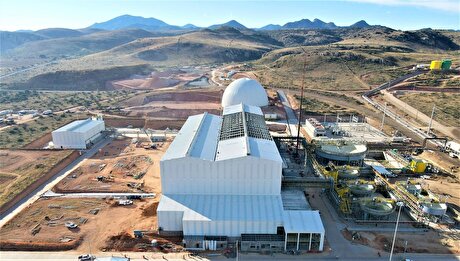

SMS group was awarded the order to supply a continuous hot-dip galvanizing line and a recoiling line for a new plant in Mexico by NUCOR-JFE STEEL MEXICO. The hot-dip galvanizing line will produce 400,000 tons of steel strips per year, most notably deep-drawing grades and high-strength steels for the automotive industry, including modern dual-phase steels. Furthermore, the line is designed to process not only cold strip but also hot strip material. Startup is anticipated for the second half of 2019.

Starting in the second half of 2019, NUCOR-JFE MEXICO will operate the new hot-dip galvanizing line from SMS group, which is designed for a yearly production of 400,000 tons of high-quality galvanized strips for the automotive industry.

NUCOR-JFE STEEL MEXICO is a 50-50 joint venture of Nucor Corporation, USA, and JFE Steel Corporation, Japan, which will build and operate the plant in central Mexico to supply that region’s automotive market. Besides the design and production of the mechanical equipment, the complete electrical and automation package also is within the supply scope of SMS group.

The hot-dip galvanizing line is designed for strips with a thickness of 0.4 to 2.6 millimeters and widths ranging from 800 to 1,880 millimeters. In the process section the strip will be coated with zinc at a process speed of up to 180 meters per minute, whereas in the entry and exit sections speeds of up to 280 meters per minute can be reached. The strip steel grades manufactured are mild steel, deep-drawing grades and high tensile strength steel. The surfaces of the strips will either be galvanized or galvannealed.

One highlight is the advanced furnace technology from Drever International which allows an economical production of high-strength material. The highly efficient combustion system features recuperative burners. Furthermore, the furnace consists of a powerful rapid gas jet cooling system, which offers upgrade possibilities. All furnace parameters and coil sequencing are controlled automatically by a mathematical/physical furnace model.

The cleaning section consists of efficient vertical electrolytic cleaning and rinsing cells and horizontal brushing machines. The skin pass mill ensures an optimized surface roughness and slight linear expansion. A vertical roll coater system with drying and cooling devices from Drever will be used for the chemical treatment of the coated surfaces.

In total, the new hot-dip galvanizing line consists of the following essential components: entry section with two uncoilers, welding machine, entry strip accumulator, cleaning section, radiant tube furnace, galvanizing section with zinc pot, intermediate accumulator, skin pass mill, vertical roll coater system, exit accumulator, side trimmer, inspection section, oiling machine, flying shear and two coilers.

The supply scope also includes a recoiling and inspection line. This line features pay-off reel, welding machine, side trimmer, inspection station, oiling machine, cut-to-length shear and upcoiler. It is also designed for strips with a thickness of 0.4 to 2.6 millimeters and widths ranging from 800 to 1,880 millimeters. The maximum line speed is 300 meters per Minute.

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

UBS lifts 2026 gold forecasts on US macro risks

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

Afghanistan says China seeks its participation in Belt and Road Initiative

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery