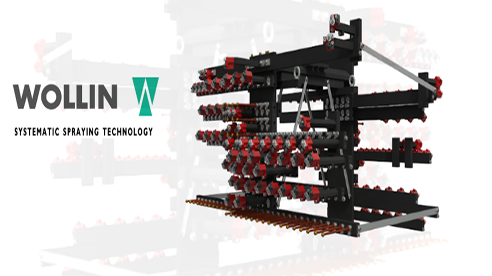

Wollin: Newly developed mould spraying machine ESM

Lots of innovations

With the exception of the proven guide rails, most of the mechanical parts have been replaced. In particular, the integration of options such as flow measurement, pressure control and pressure booster have been integrated into the horizontal axis to reduce the space required on the die casting machine and the weight on the vertical axis. The design has been reinforced and the stability of the axes has been improved by improving the useful length of the previous guides, resulting in a 25% increase in payload. The ESM is comparable to the previous PSM mould spraying machine in terms of space requirement and console position. Service accessibility has been significantly improved.

Thanks to the complete Industry 4.0 implementation, it is possible to integrate all functions and settings into the user interface of the die casting machines with the newly developed PC3 control. The PC3 already takes future safety requirements into account.

Since the trend in die casting is towards micro-spraying, the supply line for the release agent concentrate has already been integrated into the machine, which considerably simplifies the extension of the Eco-Spray option and the use of dosing nozzles. The selection of release agents for conventional spraying or concentrate spraying is now possible without disassembling the spray tool.

EcoSpray

Microspraying with Wollin EcoSpray is becoming more and more important in the current climate debate. By eliminating waste water, reducing release agent consumption and significantly reducing the energy required for compressed air and die temperature control, production conditions in die casting are becoming much more environment-friendly. By reducing the thermal shock caused by strong cooling with water, heat cracks can also be considerably reduced and the die service life significantly increased (+50 to 300%). The component quality is also improved with regard to porosity and surface quality.

The low additional costs for a little more complex mould temperature control and spray technology are very quickly amortized by the savings achieved, often within a few months.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook