Euroguss 2020: Grenzebach shines with broad portfolio

Higher quality and efficiency in post-processing of high-pressure die casting components, Friction Stir Welding for aluminum components for electro mobility combined with a high automation competency: at the Euroguss from January 14th till 16th, 2020 in Nuremberg, Grenzebach presents a wide product spectrum of solutions to the visitors (hall 8, booth 331).

Friction Stir Welding for E-mobility

During the Auto Summit in Berlin early November, politicians, association representatives and industry members once more emphasized their commitment to electro mobility. New mobility concepts, such as traveling with “green” electric power, have a direct impact on the development of casting components.

“We observe an increased demand for welding of die cast components in the automotive industry, such as the manufacturing of battery trays or heat exchangers for electric vehicles. This is where our Friction Stir Welding solution can make a difference”, says Sahin Sünger, Product Manager for Friction Stir Welding at Grenzebach.

Commonly, this involves work with cavity-prone die cast parts with uneven surfaces, which is extremely difficult to do with conventional welding technologies. This is where Friction Stir Welding makes the difference. A rotating tool generates the required process heat at the seam with friction and pressure. The material becomes plastically deformable with the heat applied and is stirred along the joint with the rotation of the tool.

Scalable solutions focused on efficiency

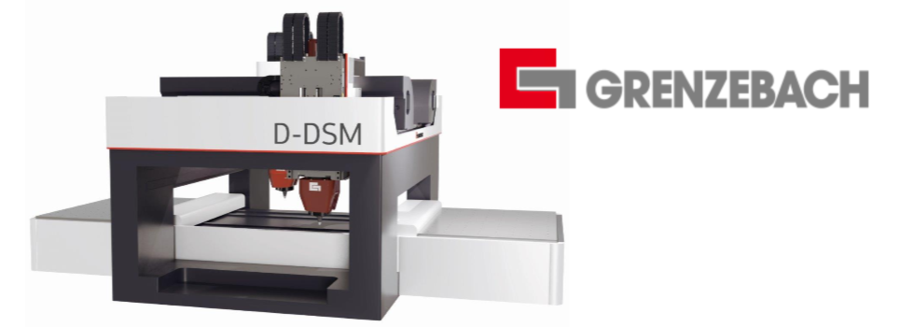

The FSW technology enables the production of durable and media-tight weldings. Since Friction Stir Welding is a solid state joining technology, no pores or hot cracks are generated. Exactly these effects are very common to conventional fusion welding. Grenzebach stands for scalable FSW solutions for serial production. The double spindle FSW gantry units of the D-DSM series provide two independently working welding heads.

“With this innovation, our customers can reduce their effective cycle time. Besides the dynamics and the welding speed, the quick loading and unloading of the machine are critical for cycle time and economic efficiency. Our customers can benefit from our expertise of numerous successful projects”, says Sahin Sünger.

Aluminum still on the rise

The FSW technology more and more complements the foundry technology, also due to the fact that aluminum substitutes steel! The automotive and aviation sector count on lightweight components; in mechanical engineering, aluminum ideally withstands mechanical stresses.

“The quantity of processed aluminum in vehicle bodies increases every year. Especially in the automotive industry changes are under way. That is why support our customers with the use of FSW technology and the development of new products offering consulting services and sample weldings”, says Sünger.

Complete added value of casting parts

Grenzebach is also a partner for the efficient manufacturing of classics, high-quality pressure die casting parts. The company collaborates with various foundries and has a supply chain of different molding procedure products. Milling, lathe turning, drilling: Grenzebach handles all processing steps for casting parts. In the machining center at the Grenzebach location in Jiashan, China, a full CNC and multiple-axes machine park is available. Grenzebach uses all painting procedures for casting parts available for the surface treatment. The automated Grenzebach paint-shop stands for high-quality results. Grenzebach processes more than 10.000 tons of die-cast parts per year. The casting parts are used in special machinery of automation industry, such as industrial robots or machine tools.

“For high-quality industrial die-cast parts, our experts developed a particular passion. We work individually on mould and model construction and together with the customer develop casting parts – always focused on the optimized serial production. Grenzebach stands for short lead times and additional added value”, says Thomas Liu, Head of Casting at Grenzebach.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook