BMW Group invests in Austria in the Future of its Powertrain

- In 2019, more than 200 million euros will be spent on new diesel engines and test stands for electric drives

- Austrian knowledge network: Research cooperations with domestic institutions continue at a high level

- Steinparzer: "Future of the drive also arises in Austria" Steyr

Steyr not only has the world's largest engine plant, but also the BMW Group's world's only diesel engine development center. Here, 700 technicians, engineers and skilled workers work with state-of-the-art test and measurement technology to make the engines of the future even more emission-efficient, efficient and powerful. For this purpose, more than 200 million euros will be spent in 2019 alone.

"Our new generation of diesel engines will start in 2020. These engines bring savings in fuel consumption and thus also in CO2 emissions of up to nine percent, "says Fritz Steinparzer, Head of Diesel Engine Development. "We will continue to develop the diesel in the future. New vehicles with current diesel technology are a very effective contribution to the fight against climate change. No combustion drive is so efficient and economical. "

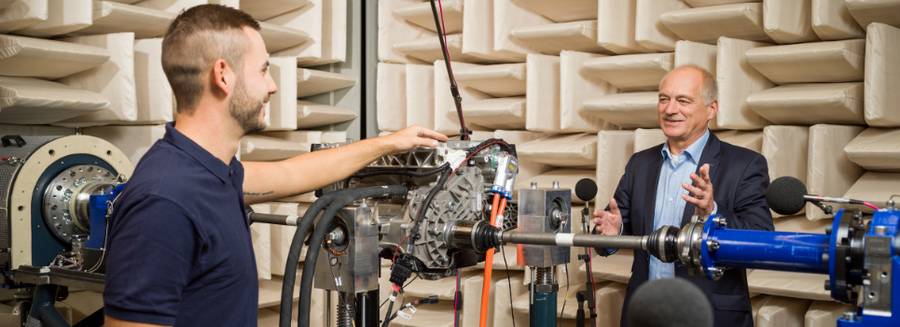

In addition, the activities for electromobility are being continually expanded and new test beds are being set up. Only recently in operation is an acoustic test bench for electric drives. The sound measurements carried out here provide valuable insights for the further optimization of the components. The complete powertrain test is unique and very efficient in this form. Saves you in many applications, the time-consuming and costly construction of a complete vehicle.

"Our know-how in drives does not stop with the internal combustion engine: highly complex components for electromobility are already being developed at our site today. The cooling circuits for the upcoming battery electric vehicles will also be developed and tested here in Steyr, "says Steinparzer.

All in all, the development center has 41 state-of-the-art test benches, which can map almost any driving condition - including minus 40 degrees Celsius and 5,000 meters above sea level. In addition to 34 engine test stands, there are seven chassis dynamometers for overall vehicle testing. Further protection is provided by test vehicles on the road.

Ad

Incidentally, sustainability and efficiency are not only a top priority for the BMW Group's engines: the waste heat from the engines during the test run is fed into the heating circuit via heat recovery, which means a 70 percent reduction in heating demand in the development center.

In addition to the development center, Steyr also owns the largest engine plant and the largest production facility for drive components in the BMW Group.

"Individual mobility will remain a basic human need worldwide. We assume that vehicle sales in the premium segment will increase. Therefore, we continue to invest in combustion engines, but we also equip ourselves in the area of electromobility. As the driving force behind the BMW Group, we are optimally positioned for the future, "says Christoph Schröder, Managing Director of the Steyr plant.

4,500 employees work at the site. Up-to-date knowledge is provided: Every year, around 70 students are given the opportunity to complete practical assignments or to write their thesis at the Steyr factory. In addition, there are cooperations with various universities and colleges, such as the Graz University of Technology, the Vienna University of Technology, the MU Leoben and the Upper Austrian universities of applied sciences as well as various industrial companies in Austria.

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Gold Fields nears $2.4B Gold Road takeover ahead of vote

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Cleveland-Cliffs inks multiyear steel pacts with US automakers in tariff aftershock

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Tailings could meet much of US critical mineral demand – study

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Glencore targets 1Mt of copper in Argentina over coming decade

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Glencore targets 1Mt of copper in Argentina over coming decade

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

Abcourt readies Sleeping Giant mill to pour first gold since 2014