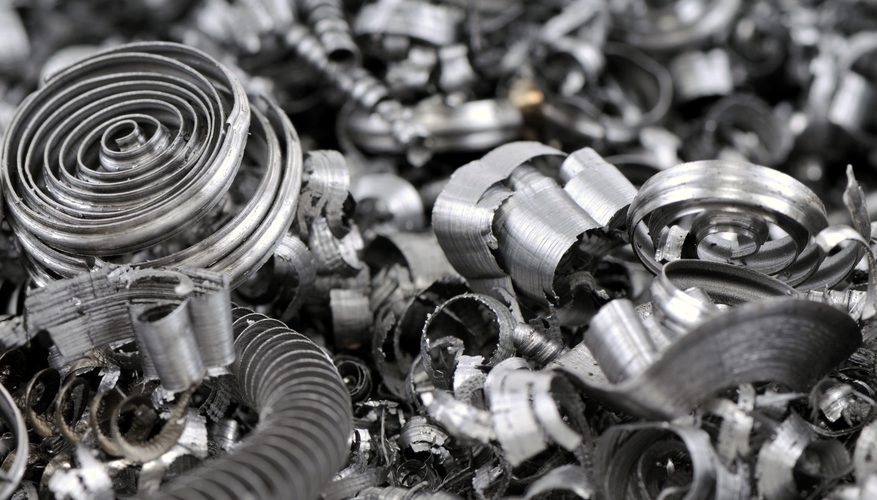

ISRI Commodities Roundtable Forum highlights oversupply in aluminium scrap and primary aluminium market

Doug Hilderhoff, a principal analyst of London-based CRU Group said an oversupply of primary aluminium is pushing the price down.

As for the scrap market is concerned; the condition is similar in the North American market struggling with excess scrap. Becky Proler, the president of Southern Core Recycling, Houston, said an excess of 6000 and 5000 series automotive aluminium scrap has dragged down the market.

Hilderhoff said, though importance of recycling is growing because of the increased focus on sustainably produced aluminium, the domestic market supply is more than abundant because of drop in export to China, the “leaking” of automotive scrap from closed-loop recycling programs and the decline in domestic can sheet production.

Hilderhoff forecasts a 0.5% drop in primary aluminium production in China in 2019 and a 5% increase in 2020. Rest of the world production is projected to increase by 2.7% in 2019 and by 2.9% in 2020. He projects a consumption drop by 1.1% in 2019 before 1.5% increase in 2020.

According to him, China is closing older smelter and adding new high-tech ones for more productivity, hence, no drop in production. He forecasts 39 million tonnes of aluminium production in China in 2020.

CRU is forecasting that the metal will end 2020 in the $1,900 per tonne range.

China has implemented quotas for aluminium scrap import, which would limit the import of aluminium scrap to only 1.2 million tonnes in 2019. Earlier, the county used to import 70% of U.S. aluminium scrap which has dropped to 20% now.

He said that India is the next best alternative market for U.S. exporters of aluminium scrap, as the country imports 85% of its aluminium scrap requirement.

Karsten Faak, recycling director at primary and recycling aluminium producer Trimet Aluminum said while the company produces 240,000 tonnes of recycled aluminium products annually it consumes some 300,000 tonnes of scrap. He highlights a drop in demand from automotive sector that consumes about 60% of its products.

He said that a shift to electric vehicles likely will further reduce Trimet’s supply to the automotive market as these vehicles use fewer secondary aluminium castings. Currently, secondary castings account for 56% of the aluminium used in vehicles, which will drop to 25%in electric battery powered cars.

To survive the current market, Proler said scrap processors would have to be “flexible in your business plan and model.” She also said that the crisis is actually giving an opportunity to the scrap industry to innovate and work together.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook