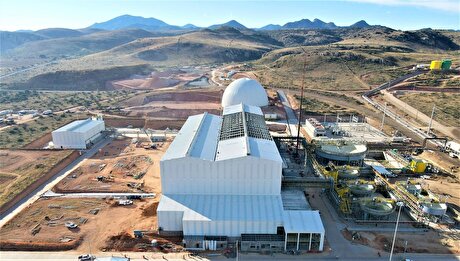

Alcoa introduces VR training for its alumina refinery workers

The guided training module replicates an environment of Alcoa’s refinery sub-station where the trainees are surrounded by equipment, sound, and personal protective equipment (PPE) that are found in real in the workplace. The module demonstrates how to safely and correctly isolate electrical switches to avoid arc flash incidents.

Besides, Alcoa has incorporated free-play environments which include events and risks to mitigate, replicating what could occur in real life.

According to Alcoa’s Pinjarra refinery manager Mark Hodgson, this step is taken for bringing in a change in the way training is usually delivered at refineries and also to make trainees aware of more safety measures.

“With safety being our top priority, this training allows our employees to experience high-risk hazards and the steps to mitigate them in a safety environment, so they can take what they have learned back to their workplace,” Hodgson said.

The team is working on deploying similar training modules for several high-risk tasks, including working on or near energised equipment and high-voltage isolation.

The company believes VR training can provide a learning retention rate of 75 per cent, compared to 20 per cent with standard computer-based point-and-click training.

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

UBS lifts 2026 gold forecasts on US macro risks

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

Afghanistan says China seeks its participation in Belt and Road Initiative

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery