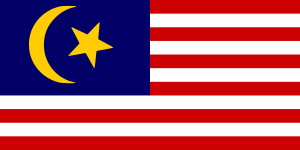

Malaysia allows Lynas to continue operating rare earths plant for six months

Among the requirements imposed by the Atomic Energy Licensing Board (AELB), an agency under the Ministry of Energy, Science, Technology, Environment and Climate Change, Lynas must outline a plan to set up its cracking and leaching facility overseas, within four years of the licence renewal.

The company, the world’s only major producer of rare earths outside China, will also have to identify a specific site, approved by Malaysia, for a permanent disposal location for its low-level radioactive waste. Alternatively, Lynas will have to secure official written approval from a recipient country willing to take the waste, the regulator said.

Lynas must outline a plan to set up its cracking and leaching facility overseas, within four years of the licence renewal

Analysts reacted positively to the news, saying that the four-year deadline suggested that a longer licence renewal would be forthcoming if Lynas meets the imposed requirements. Licence renewals in Malaysia are usually given for three years.

Opponents, as expected, lambasted the government’s decision. “Those conditions have been part of the temporary operating licence since 2012,” Tan Bun Tee, chairman of Save Malaysia, Stop Lynas (SMSL), said in an emailed statement. “Lynas has never bothered to comply with them so what is the point?”

“Malaysia’s weak regulatory regime and culture, tropical rainstorms that often lead to landslides and soil erosion present safety, reliability and technical challenges for any mega-physical structure such as the requested permanent disposal facility (PDF),” he noted.

Dragged-out complaints

The Sydney-based company, which extracts rare earths in Western Australia, but processes them in Malaysia, has faced several issues related to its six-year-old facility in the country — known as the Lynas Advance Material Plant (LAMP).

LAMP was the centre of relentless attacks from environmental groups and local residents while under construction in 2012. They feared the impact the low-level radioactive waste the refinery generates could have on the health of those living nearby, and to the environment.

Scrutiny escalated last year, with Kuala Lumpur setting a committee to review Lynas’ operations. At the time, chief executive and managing director, Amanda Lacaze, raised concerns about the impartiality of a couple of committee members, both long time opponents of having the refinery located in Malaysia.

In December, the AELB told Lynas it had to remove 450,000 tonnes of waste stockpiled at the local facility by September 2, the day its licence was due to expire.

Licence extension comes amid concerns that the rare earths industry may get embroiled in the trade war between China and the US

The miner ended up committing to build a first-stage processing plant in one of two preferred sites in Western Australia, where its Mt Weld mine is located. Downstream processing, however, was set to continue happening in Malaysia.

The licence extension comes amid concerns that the rare earths industry may get embroiled in the trade war between China and the US.

Lynas said in June that it had begun stockpiling output following Beijing’s threats to stop exporting rare earths as a weapon against the US, which imports about 80% from China.

The nation has used its rare earths dominance to make a political point in the past. It blocked exports to Japan after a maritime dispute in 2010, though the consequent spike in prices triggered a race to secure supplies elsewhere.

Experts believe that would be the risk again if Beijing follows through with its retaliation warnings. Lynas’ main products, neodymium and praseodymium, are key ingredients in permanent magnets used in electric vehicles, energy efficient consumer devices, and in the aerospace and defence industries.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook