World largest straightener at ArcelorMittal Differdange

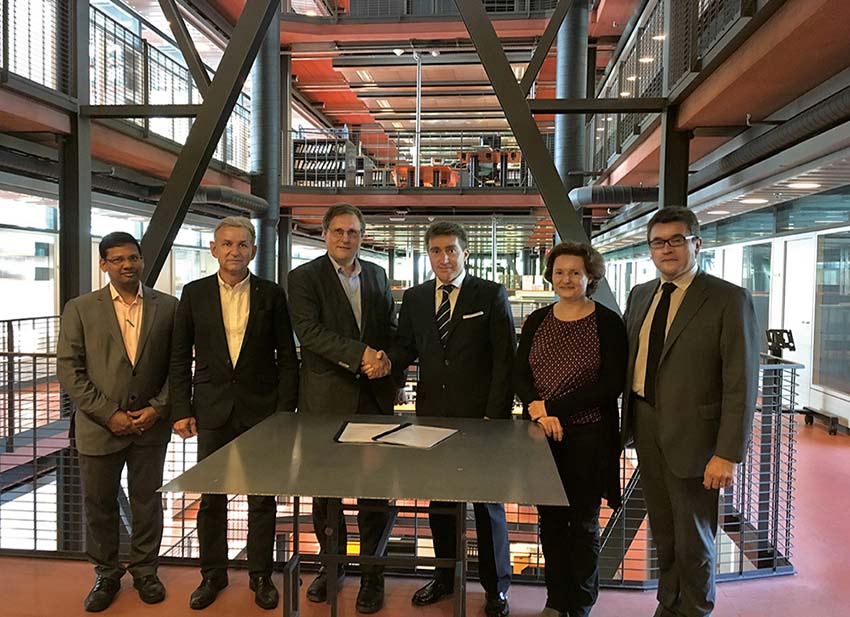

Signing of the Contract at ArcelorMittal Esch-Sur-Alzette (From left: Mr. K. Bansal, GM Capital Goods, AM; Mr. C. Koepp, CEO Differdange, AM; Mr. A. Nick, VP & CEO Business Division North, AM; Mr. L. Maestrutti, EVP, Danieli; Mrs. I. Dejardin, Manager Purchasing, AM; Mr. L. Gori, Sales Director, Danieli Morgårdshammar).

Signing of the Contract at ArcelorMittal Esch-Sur-Alzette (From left: Mr. K. Bansal, GM Capital Goods, AM; Mr. C. Koepp, CEO Differdange, AM; Mr. A. Nick, VP & CEO Business Division North, AM; Mr. L. Maestrutti, EVP, Danieli; Mrs. I. Dejardin, Manager Purchasing, AM; Mr. L. Gori, Sales Director, Danieli Morgårdshammar).

ArcelorMittal has ordered to Danieli new finishing equipment for its jumbo beam mill in Differdange.

The core of the project consists in the installation of a new 9-roll straightener to replace the manual straightening operations which are currently accomplished by using two gag presses.

With a 2,500-cm3 modulus, the new straightener for ArcelorMittal will be the largest ever built.

The double-support design of the new Danieli heavy-duty machine will allow both web and flange-tip straightening. Fully hydraulic rolls adjustment system. Automatic roll change of all 9 straightening rolls will take less than 25 minutes.

The extension of the existing cooling bed, a new cold disc saw and related handling equipment including an automatic system to transfer the rolls from the production line to a new roll setup and preparation area, will complete the plant upgrade.

All electrical and automation systems will be provided by Danieli Automation.

Plant start-up is scheduled for the beginning of 2018.

More information about the plant:

ArcelorMittal Differdange mill was already upgraded by Danieli in 2007 with the installation of intermediate reversing mill stands featuring Hydraulic Gauge Control. Differdange mill product range includes parallel-flange beams and columns with up to 1,138-mm web width, up to 476-mm flange height, up to 140-mm flange thickness and up to 1,377-kg/m linear weight, in high-strength steel grades, such as ASTM A913 grades 70 (485 MPa), 65 (450 MPa) and 50 (345 MPa) or EN 10025 grade S460M.

Such Jumbo beams have been used in extreme engineering projects around the world, including the Freedom Tower in New York, the Shanghai World Trade Center, and the upper part of the Burj Khalifa in Dubai.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Barrick’s Reko Diq in line for $410M ADB backing

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts