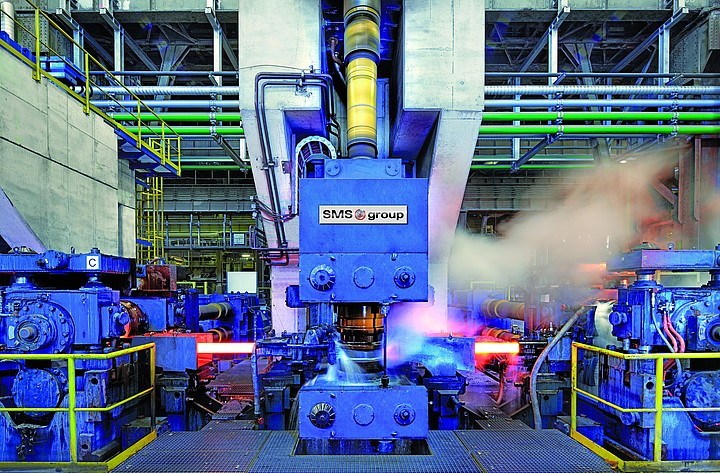

Fujian Luoyuan Minguang Iron and Steel orders section mill from SMS group

The new section mill will enable Fujian Luoyuan Minguang Iron and Steel to broaden their product portfolio and to respond to the high demand for beams in the region and in the People's Republic of China.

The section mill will be designed for an annual capacity of 1.3 million tons and equipped with a state-of-the-art breakdown stand and the latest-generation CCS® universal mill stands in reversing tandem arrangement, featuring hydraulic adjustment systems and automatic quick program change. The new CRS® roller straightening machine, which is also equipped with hydraulic adjustment systems ensures minimal program change time as well as best straightness and minimal residual stress level of the finished products.

Furthermore, SMS group’s scope of supply includes the technology and engineering for the entire rolling mill, the supply of hot and cold saws, the PROGAUGE in-line profile gauge with surface defect detection (SurfTec) and other mechanical key components. The supply will be complemented by the basic automation for the rolling mill as well as electrical main and auxiliaries drives.

The supervision of erection and commissioning as well as the commissioning of the electrical equipment and automation will be done by SMS group. The theoretical training of the customer’s personnel will be held in SMS group training center in Mönchengladbach. Further practical training will be provided at site during erection and commissioning by SMS group.

The technological know-how, the proven top equipment and the commissioning expertise were factors in the customer’s decision to select SMS group as partner for this strategic project. Hot commissioning is scheduled for second half of 2020.

Signing ceremony with Elmar Krieg, Head of Sales Section & Billet Mills, SMS group, Hu Yuyan, Section Chief of Equipment Department, Fujian Luoyuan Minguang Iron and Steel Co., Ltd. and Wang Guoshun, General Manager, SMS group China Long Product Division.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook