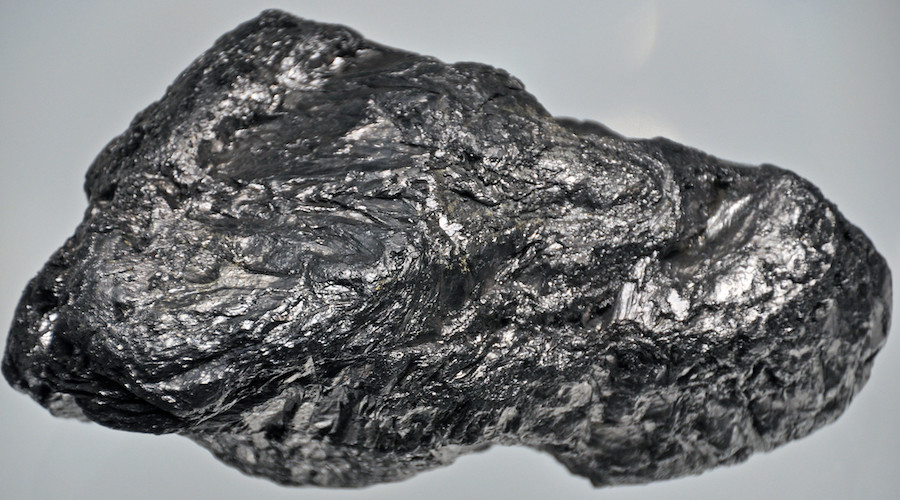

ZEN partners with Canadian university to produce low-cost graphene

In a press release, the company explained that the production process rapidly exfoliates Albany graphite into few-layer graphene or FLG with a conversion efficiency of over 90%.

TheAlbany graphite project is located near Thunder Bay, in northeastern Ontario. It is a microcrystalline graphite deposit with a completed PEA

“The challenge in the emerging graphene industry has been to produce consistent FLG, available in industrial quantities at prices that permit industrial adoption,” Francis Dubé, ZEN's CEO, said in the media brief. “We believe that with this exciting new process applied to our unique Albany Graphite product, ZEN Graphene Solutions possesses all the components to solve this challenge within a single vertically integrated company.”

According to Dubé, the company collected 110 tonnes of graphite-mineralized material with an estimated average grade of 6% graphitic carbon during a bulk sample program that was carried out in early 2019.

The collected material is going to be purified into approximately 99.8% graphite. This exfoliation process combined with other techniques will be used to transform the graphite into graphene and graphene oxide.

“The company has commenced searching for an industrial location that will house a pilot production centre, a research and development lab as well as office space. The graphene produced by the pilot production centre will be offered for sale as permitted by the Ministry of Northern Development and Mines,” Dubé said.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook