World's first multiflex-quench® successfully commissioned by SMS GROUP at ACRONI in Slovenia

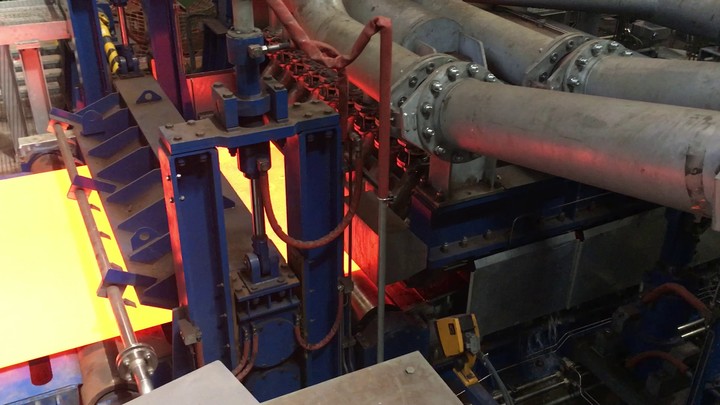

The new heavy-plate heat treatment line supplied by SMS group for Acroni in Slovenia consists of an innovative MultiFlex-Quench® and two roller hearth furnaces.

On June 30th, 2016, the MultiFlex-Quench® newly developed by SMS group has successfully produced its first heavy plate in the Acroni plant in Jesenice, Slovenia. This goal has already been reached two days in advance of the scheduled date. Plate flatness was excellent right from the start. Two powerful roller hearth furnaces are further key components of the new heavy-plate heat treatment line at Acroni. The plant was supplied completely by SMS group and it is designed to produce at least 80,000 tons of heavy plate per year.

"This is a very important day and we do thank SMS for the good cooperation and support, vital for this achievement. The flatness of the first plate looks already very good. We are now targeting to complete the coming activities and optimizations smoothly," stated Blaz Jasnic, General Manager of Acroni, a company of the Slovenian Steel Group (SIJ). Acroni is a highly specialized supplier focusing on plates and strips made of stainless grades, tool steels, abrasion-resistant steels and HSLA grades. Acroni is further expanding its product portfolio with the new heat treatment line. The importance of the new line has been emphasized by the presence of Prof. Dr. Vasilij Prešern (SIJ group), Roman Robic (Technical Director of Acroni) and Konstantin Pitul (Vice President of KOKS group owner of SIJ).

The line is equipped with a high-temperature roller-hearth furnace for hardening and normalizing. The furnace consists of two chambers, in which the plates are annealed in a nitrogen-based inert gas atmosphere. Radiant tubes heat the material indirectly up to 1,100 °C.

The innovative MultiFlex-Quench® stands out by its exceptionally high degree of flexibility. Contrary to conventional quenches, this type offers variable setting options. Thus, all cooling patterns from slow cooling to abrupt quenching can be covered to achieve a wide product portfolio. Furthermore, the MultiFlex-Quench® offers improved plate flatness due to active hydraulic clamping.

The line is also equipped with a new low temperature furnace for plate re-heating. In this open-fired roller-hearth furnace the plates can be quenched and tempered at temperatures between 400 and 800 °C.

The scope of supply includes also all auxiliary facilities such as the complete plate conveying equipment, all systems for water management and treatment as well as the electrical and automation systems.

The plant is designed for plates with thicknesses ranging from three to 100 millimeters and a maximal width of 2,500 millimeters. The product portfolio includes among others high-strength carbon steels, stainless and tool steels as well as a number of special grades. Within the project, SMS supports Acroni also in the development of heat treatment cycles for new material grades, which are deposited in the Level 2 online model for controlling the thermal process.

The first heavy plate runs into the newly developed MultiFlex-Quench® in the Acroni heat treatment line.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook