First coil on Angang’s new galvanizing line from SMS GROUP

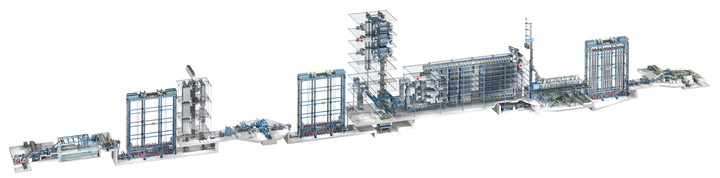

After completion of commissioning the new Angang continuous galvanizing line in Guangzhou, China, will produce 450,000 tons per year of high-quality galvanized or galvannealed cold-rolled strip for the automotive industry.

The heat treatment and galvanizing of the first coil marked the start-up of the new continuous galvanizing line built for Angang (Angang Guangzhou Auto Steel Co.) near the city of Guangzhou in the province of Guandong, China. As one-source supplier, SMS group was responsible for the engineering, the process, furnace and galvanizing technology as well as the electrical and automation systems for the complete plant.

Upon completion of the commissioning phase, the line will be able to produce 450,000 tons of galvanized or galvannealed steel strips per year, serving the automotive and home appliances industries in South China and the Pearl River Delta. Most notably, deep-drawing grades and high-strength steels for the automotive industry will be produced, including modern dualphase steels. Aside from automotive structural components, strips with a high-quality steel surface will be produced for use in exposed vehicle parts.

To achieve high cooling rates, a vertical radiant tube furnace with an ultra-fast cooling system from Drever has been integrated. A further highlight of the furnace is the pre-oxidation chamber, which allows steel grades with high manganese or silicon contents to be galvanized without wettability problems. A high-quality air-knife system from DUMA-BANDZINK has been integrated for the galvanizing process. Highest surface qualities are achieved, among other things, due to modern facilities such as a patented radial controller, an automatic air knife lip cleaner and a knife gap width adjustment system. Drever and DUMA-BANDZINK are both companies of SMS group.

Further components decisive for the high quality achieved by the continuous galvanizing line are the high-performance cleaning section, the four-high skin-pass mill, the tension leveler, the vertical roll-coater with a Drever drying and cooling system, the ASC side trimmer with integrated scrap chopper and the electrostatic DUMA-BANDZINK oiling machine.

The line is designed for strips with dimensions of typical car sheets. In the process section the strip will be coated with zinc at a process speed of up to 160 m/min, whereas in the entry and exit sections speeds of up to 220 m/min can be attained. The steel grades produced will include CQ, DQ, DDQ, EDDQ, HS and DP.

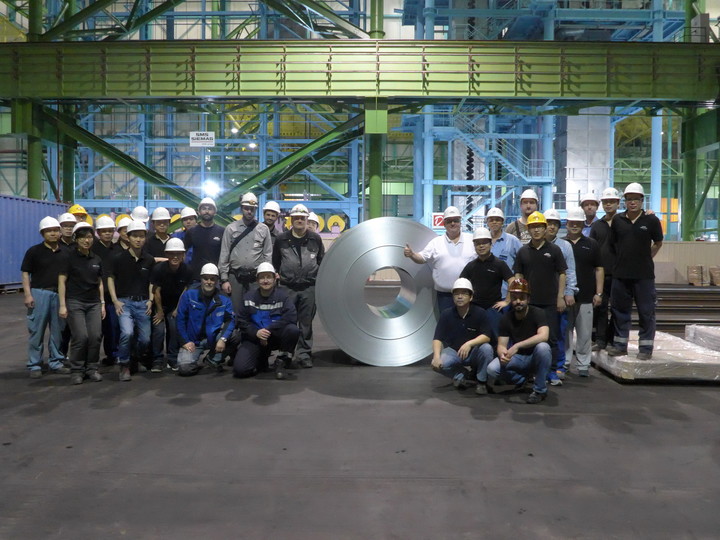

The commissioning team with the first galvanized coil

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook