Thirty-year-old inactive mine to host Australia’s first clean energy storage facility of its kind

The developer is Toronto-based Hydrostor, a firm that was awarded $9 million in grants to build the facility, which would allow for variable renewable energy resources such as solar and wind to be integrated into Australia’s National Electricity Market.

According to Hydrostor, the project will repurpose Angas’ existing underground mining infrastructure as the A-CAES system’s sub-surface air storage cavern.

In a media brief, company experts explained that the way the technology works is that it uses electricity from the grid to run a compressor, which produces heated compressed air. Heat is then extracted from the air stream and saved inside a thermal store preserving the energy for use later in the cycle.

The compressed air is then stored in a purpose-built underground cavern, which is kept at a constant pressure using hydrostatic heat from a water column. During charging, compressed air displaces water out of the cavern up a water column to a surface reservoir, and during discharge water flows back into the cavern forcing air to the surface under pressure where it is re-heated using the stored heat and then expanded through a turbine to generate electricity on demand.

“Compressed air storage has the potential to provide similar benefits to pumped hydro energy storage, however, it has the added benefits of being flexible with location and topography, such as utilising a cavern already created at a disused mine site,” said Darren Miller, CEO of the Australian Renewable Energy Agency, the institution that provided $6 million for the project.

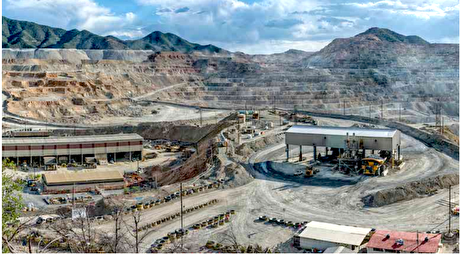

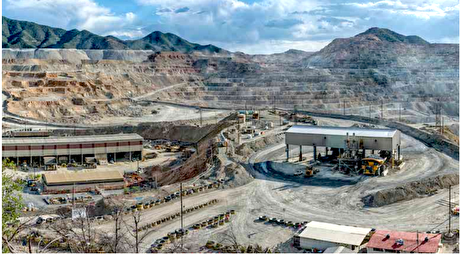

The Angas zinc mine, first discovered in 1991 and acquired by local miner Terramin (ASX: TZN) in 1997, is located on the Fleurieu Peninsula in South Australia. It was placed under care and maintenance in late 2013 as a result of a prolonged drop in metal prices and the current economic reserve being depleted.

The processing plant at Angas was decommissioned but Terramin has been maintaining it with the idea of processing there the ore from its Bird-in-Hand gold project, which is located approximately 30 kilometres north of the zinc mine.

According to the miner, if it gets the required regulatory approvals, its team would modify the plant to process gold-bearing material, while also making use of the existing tailings dam.

Based on Terramin’s December 2018 quarterly activities report, the possibility of restarting the processing plant at Angas does not collide with Hydrostor’s work at the site.

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

Chile’s 2025 vote puts mining sector’s future on the line

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Gold price could hit $4,000 by year-end, says Fidelity

Three workers rescued after 60 hours trapped in Canada mine

US targets mine waste to boost local critical minerals supply

Glencore workers brace for layoffs on looming Mount Isa shutdown

Column: EU’s pledge for $250 billion of US energy imports is delusional

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming