solidThinking Design Study: Wisconsin Precision Casting Corporation

By utilizing the latest technologies and expertise in investment casting WPC provides customers with solutions to save time, money, and stress. From the customer’s initial design to the final product, WPC offers support throughout the entire casting process. Whether it’s engineering support, alloy selection or part size, WPC continues to exceed customer expectations for service, quality, cost and ontime delivery.

Trends in casting continue to evolve in order to adapt to industries in which casted parts are used. In order for WPC to meet the demands of these industries and its customers, it is imperative that the latest technologies, machines, and tools are employed. During a recent design study with Altair, the optimization and redesign of a regenerative turbine pump cover was investigated. Regenerative turbine pumps allow fluid to travel through the vanes of the pump multiple times, while centrifugal pumps only allow fluid to travel through the centrifugal impeller once. Regenerative turbine pumps are capable of high pressure and require close tolerances to perform efficiently. The goals for this redesign were to reduce material usage in the pump’s cover, maintain original strength and performance and improve casting efficiency. WPC provided casting expertise while Altair provided structural analysis expertise using its simulation tools, Altair Inspire and Altair Click2Cast®.

During a recent design study with solidThinking, the optimization and redesign of a regenerative turbine pump cover was investigated. Regenerative turbine pumps allow fluid to travel through the vanes of the pump multiple times, while centrifugal pumps only allow fluid to travel through the centrifugal impeller once. Regenerative turbine pumps are capable of high pressure and require close tolerances to perform ef ficiently. The goals for this redesign were to reduce material usage in the pump’s cover, maintain original strength and performance and improve casting ef ficiency. WPC provided casting expertise while solidThinking provided structural analysis expertise using its simulation tools, Inspire and Click2Cast®.

SOLIDTHINKING IN THE DESIGN AND CASTING PROCESS

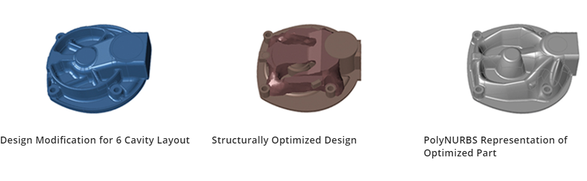

Considering the end goal of weight reduction while maintaining the part’s strength and overall performance, the redesign consisted of three phases. In the first phase, WPC inherited the original design from its customer and quickly recognized the need for a more efficient pouring process. WPC reduced the number of ingates and changed the part orientation on the sprue to allow for more parts per pour. These changes would allow WPC to spend less time degating the part while reducing the overall cost per part. This change required a substantial redesign of the cover to facilitate.

The next phase in the redesign focused on the optimization of the pump cover structure. While utilizing solidThinking Inspire, loads and critical features for casting were identified and a baseline analysis on the proven design was completed. The pump cover was then optimized in Inspire and resulted in an 8% mass reduction and increased strength. During the optimization process, casting metrics were also validated such as porosity and solidification time.

“By changing the ingate orientation and size we can greatly reduce our time per part. Being able to discuss part performance greatly increases the engineering value we can bring to the table,” explains Claude Klemowits, Vice President of Engineering, Wisconsin Precision Casting.

DESIGN STUDY RESULTS

Once the pour was completed, the final parts were x-rayed, studied and contained minimal porosity, which accurately compared to the casting analysis that was completed in Click2Cast.

This comprehensive design study allowed WPC to have a better understanding of the optimization and pour process, and provided knowledge on techniques for future designs.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook