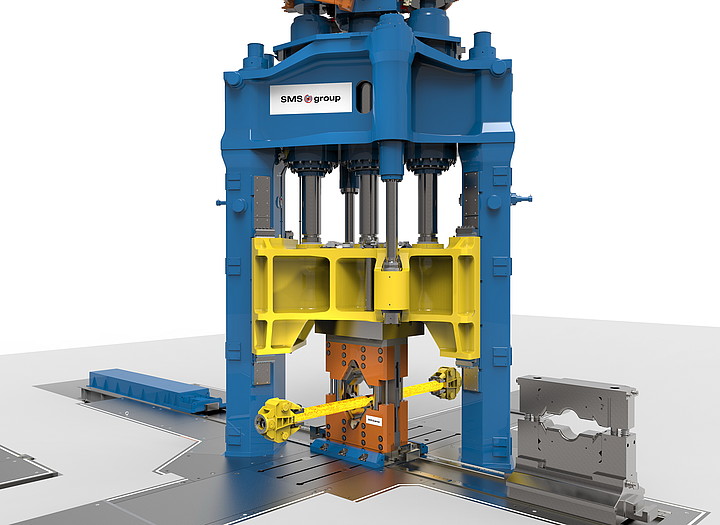

Sichuan Liuhe Forging orders high-speed open-die forging press with innovative X-Forging Box radial forging tool from SMS group

The press is of the two-column, push-down design and features a table shifter and die shifting unit. The open-die forging press operates with a press force of up to 50 MN and a maximum upsetting force of 55 MN. The press is suited for forging high-quality products with finished dimensions within the close tolerance range of ± 1 millimeters.

Sichuan Liuhe Forging is a specialist manufacturer of forged semi-finished products, reinforcing rings, shafts, parts for turbine blades, and supercritical components for gas turbines made of high-temperature, corrosion-resistant special steel and superalloys. The new press allows Sichuan Liuhe Forging to continue to offer a consistently high level of product quality to its customers in the aerospace industry and to operators of large-scale steam turbines.

“With this investment in the open-die forging press, developed and built by SMS group in Germany, we are raising our quality standards to an even higher level,” says Hong Yuchun, Vice-General Manager of Sichuan Liuhe Forging. “We are also pleased that the enhanced press control system will mean lower production costs for us.”

The order also includes an XFB (X-Forging Box) 650/50 MN, which is a newly developed radial forging tool for open-die forging presses. The XFB transforms the movement of the top tool in the open-die forging press into a radial movement of the four tools in the X-Forging Box. At the same time, the maximum permissible force of 50 MN is evenly distributed among the four tools. The maximum initial pass section is 650 millimeters. The X-Forging Box is capable of forging a wide range of high-quality round products with variable cross-sections. The use of the XFB enables Liuhe Forging to expand its product mix and quickly change between different types of products; no modifications to the tool chamber or to the hydraulic-electrical connections are required to install an XFB.

Commissioning of the 50/55 MN open-die forging press and 650/50 MN X-Forging Box is scheduled for Q4 2019.

SAIL Bhilai Steel relies on Danieli proprietary technology to expand plate mill portfolio to higher steel grades

Alba Discloses its Financial Results for the Second Quarter and H1 of 2025

Fortuna rises on improved resource estimate for Senegal gold project

Copper price slips as unwinding of tariff trade boosts LME stockpiles

US slaps tariffs on 1-kg, 100-oz gold bars: Financial Times

Fresnillo lifts gold forecast on strong first-half surge

Codelco seeks restart at Chilean copper mine after collapse

Why did copper escape US tariffs when aluminum did not?

NextSource soars on Mitsubishi Chemical offtake deal

Samarco gets court approval to exit bankruptcy proceedings

Hudbay snags $600M investment for Arizona copper project

Discovery Silver hits new high on first quarterly results as producer

Trump says gold imports won’t be tariffed in reprieve for market

AI data centers to worsen copper shortage – BNEF

Uzbek gold miner said to eye $20 billion value in dual listing

Peabody–Anglo $3.8B coal deal on the brink after mine fire

De Beers strikes first kimberlite field in 30 years

Minera Alamos buys Equinox’s Nevada assets for $115M

OceanaGold hits new high on strong Q2 results

Hudbay snags $600M investment for Arizona copper project

Discovery Silver hits new high on first quarterly results as producer

Trump says gold imports won’t be tariffed in reprieve for market

AI data centers to worsen copper shortage – BNEF

Peabody–Anglo $3.8B coal deal on the brink after mine fire

De Beers strikes first kimberlite field in 30 years

Minera Alamos buys Equinox’s Nevada assets for $115M

OceanaGold hits new high on strong Q2 results

South Africa looks to join international diamond marketing push