How to maximize platinum's efficiency in fuel cells

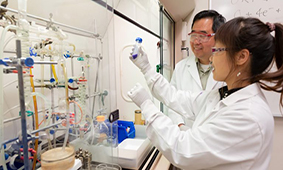

As it is widely known, when it comes to fuel cell, platinum offers both activity and stability for electrochemical reactions. However, given the rarity and price of the precious metal, the Argonne researchers have been trying to use less of it.

Up until now, large amounts of the element were used in oxygen reduction reactions but the US scientists were able to do things more efficiently. First, they tweaked the shape of the platinum to maximize its availability and reactivity in the catalyst. In this configuration, a few layers of pure platinum atoms cover a cobalt-platinum alloy nanoparticle core to form a core-shell structure.

But the core-shell nanoparticles on their own still could not handle a large influx of oxygen when the fuel cell needs to crank up the electric current. To increase the efficiency of the catalyst, the scientists produced a catalytically active, platinum group metal-free or PGM substrate as the support for the cobalt-platinum alloy nanoparticles.

By using metal-organic frameworks as precursors, they were able to prepare a cobalt–nitrogen–carbon composite substrate in which the catalytically active centers are uniformly distributed near to the platinum-cobalt particles. Such active centers are capable of breaking the oxygen bonds by themselves and work synergistically with platinum.

In a media statement, the researchers explained that the new catalyst not only improved activity but also the durability as compared to either component alone.

Previously, the experts created a patented process that involves first heating up cobalt-containing metal-organic frameworks. As the temperature increases, some of the cobalt atoms interact with organics to form a PGM-free substrate while others are reduced to well-dispersed small metal clusters throughout the substrate. After the addition of platinum followed by annealing, platinum-cobalt core-shell particles are formed and surrounded by PGM-free active sites.

"Since the new catalysts require only an ultralow amount of platinum, similar to that used in existing automobile catalytic converters, it could help to ease the transition from conventional internal combustion engines to fuel cell vehicles without disrupting the platinum supply chain and market,” said Di-Jia Liu, the corresponding author of the study in the press release.

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Roshel, Swebor partner to produce ballistic-grade steel in Canada

Iron ore price dips on China blast furnace cuts, US trade restrictions

EverMetal launches US-based critical metals recycling platform

South Africa mining lobby gives draft law feedback with concerns

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study