Iron ore miners have new price competition: Chinese scrap

Chinese mills owners who believe the steel boom is over may well take the time to prepare for a not too distant future when scrap is readily available

<p>The price of iron ore drifted lower again on Wednesday after data out of China, which consumes more than 70% of the seaborne trade in the steelmaking raw material, painted a gloomy picture of the world’s second largest economy.</p>

<p>On Wednesday the benchmark 62% Fe import price including freight and insurance at the Chinese port of Tianjin slid for the fifth straight day to $54.40 a tonne, the lowest in just over a month according to data provided by The SteelIndex.</p>

<p>The People’s Bank of China’s third quarter survey of businesses and households showed a marked deterioration in sentiment with confidence in the state of the economy falling to levels last seen during the height of the 2008-2009 financial crisis.</p>

<p>Iron ore is still trading up more than 20% from record lows for the spot market hit July 8, but remains down 54% compared to this time last year. A price below $60 all in – where the commodity has traded for the last 14 weeks –makes life difficult for all but the most cost-effective producers.</p>

<p>Smaller iron ore miners not only have to compete with majors where margins remain fat and volumes continue to grow (Rio Tinto and BHP Billiton have breakeven costs below $30) – but now there could be a new game in town.</p>

<p><br />

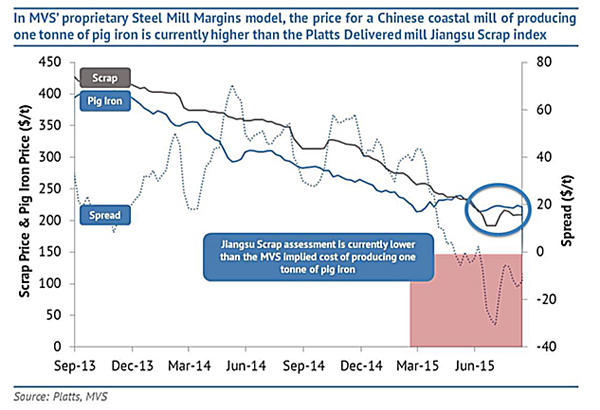

A new research report by Minerals Value Service shows the price to a Chinese coastal mill of producing one tonne of pig iron (including cost and freight of all iron ores, coking coals, sintering and pelletizing costs) is currently higher than benchmark scrap price (Platts Heavy Delivered mill Jiangsu Scrap) inside the country.</p>

<p>The fact that the Platts price is the only Chinese scrap assessment illustrates the fact that scrap supply has not in the past played much of a role in the industry, especially when compared to places like Europe where steelmakers have been known to charge up to 18% scrap to furnaces according to MVS.</p>

<p>For iron ore exporters it’s not all bad news however.</p>

<p>Due to the dominance of blast furnaces over electric arc technology and heavy excise duties, scrap imports hardly play a role in Chinese steelmaking. Last year the country imported 932 million tonnes of iron ore. Scrap imports totaled 2.5 million tonnes and was down 40% from the year before.</p>

<p>And even domestic Chinese scrap supply may not be competitive with iron ore ore imports. At least not yet:</p>

<p>“Domestic scrap prices have only been this competitive since June 2015. This may not signal a structural shift.</p>

<p>“Furthermore, the Fe content of scrap is variable (typically about 90% Fe) and yield loss may also play a role. Increasing scrap usage may also necessitate a capital outlay as steel mills ready their infrastructure. Even if steelmakers can overcome these hurdles, they still have to source the scrap in what is a very fragmented industry.”</p>

<p>But the report does carry warning however: Chinese mills owners who believe the steel boom is over, and there are many who do, may well “take the time to prepare for a not too distant future when scrap is readily available,” because "procuring equivalent Fe units at a fraction of the hassle is surely an attractive alternative to iron ore.”</p>

<p>The price of iron ore drifted lower again on Wednesday after data out of China, which consumes more than 70% of the seaborne trade in the steelmaking raw material, painted a gloomy picture of the world’s second largest economy.</p>

<p>On Wednesday the benchmark 62% Fe import price including freight and insurance at the Chinese port of Tianjin slid for the fifth straight day to $54.40 a tonne, the lowest in just over a month according to data provided by The SteelIndex.</p>

<p>The People’s Bank of China’s third quarter survey of businesses and households showed a marked deterioration in sentiment with confidence in the state of the economy falling to levels last seen during the height of the 2008-2009 financial crisis.</p>

<p>Iron ore is still trading up more than 20% from record lows for the spot market hit July 8, but remains down 54% compared to this time last year. A price below $60 all in – where the commodity has traded for the last 14 weeks –makes life difficult for all but the most cost-effective producers.</p>

<p>Smaller iron ore miners not only have to compete with majors where margins remain fat and volumes continue to grow (Rio Tinto and BHP Billiton have breakeven costs below $30) – but now there could be a new game in town.</p>

<p><br />

A new research report by Minerals Value Service shows the price to a Chinese coastal mill of producing one tonne of pig iron (including cost and freight of all iron ores, coking coals, sintering and pelletizing costs) is currently higher than benchmark scrap price (Platts Heavy Delivered mill Jiangsu Scrap) inside the country.</p>

<p>The fact that the Platts price is the only Chinese scrap assessment illustrates the fact that scrap supply has not in the past played much of a role in the industry, especially when compared to places like Europe where steelmakers have been known to charge up to 18% scrap to furnaces according to MVS.</p>

<p>For iron ore exporters it’s not all bad news however.</p>

<p>Due to the dominance of blast furnaces over electric arc technology and heavy excise duties, scrap imports hardly play a role in Chinese steelmaking. Last year the country imported 932 million tonnes of iron ore. Scrap imports totaled 2.5 million tonnes and was down 40% from the year before.</p>

<p>And even domestic Chinese scrap supply may not be competitive with iron ore ore imports. At least not yet:</p>

<p>“Domestic scrap prices have only been this competitive since June 2015. This may not signal a structural shift.</p>

<p>“Furthermore, the Fe content of scrap is variable (typically about 90% Fe) and yield loss may also play a role. Increasing scrap usage may also necessitate a capital outlay as steel mills ready their infrastructure. Even if steelmakers can overcome these hurdles, they still have to source the scrap in what is a very fragmented industry.”</p>

<p>But the report does carry warning however: Chinese mills owners who believe the steel boom is over, and there are many who do, may well “take the time to prepare for a not too distant future when scrap is readily available,” because "procuring equivalent Fe units at a fraction of the hassle is surely an attractive alternative to iron ore.”</p>source: mining

Top News

One last month

Four last month

Five last month

Seven last month

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook