Quick upgrade to rolling mill automation control system without disruption to plant production

Recently, Danieli Automation performed the switchover from the obsolete control system (Siemens Simadyn) to the new HiPAC controller for Roughing Mill Stand N.1.

The HiPAC was seamlessly integrated into the existing automation system during normal production, without any dedicated shutdown time.

HiPAC proved to be the best solution to upgrade the widely adopted Siemens Simadyn control system.

Comment by Cobus Smit, Automation Project manager, ArcelorMittal South Africa:

“I congratulate all involved with the recent successful upgrade of rack NX31 used for Roughing Mill Stand No.1 control functions. Following the switchover to the new controller on 01/11, and the subsequent start-up after the shutdown, no significant issues have been reported. Given the scope and technical complexity associated with the integration and commissioning activities, I believe this is a significant achievement.”

Samarco gets court approval to exit bankruptcy proceedings

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Cochilco maintains copper price forecast for 2025 and 2026

Gold price stays flat following July inflation data

Mosaic to sell Brazil potash mine in $27M deal amid tariff and demand pressures

Glencore seeks $13 billion in incentives for Argentina copper projects

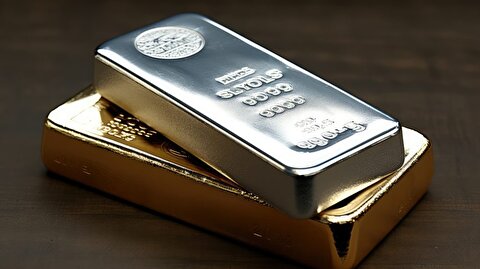

HSBC sees silver benefiting from gold strength, lifts forecast

Hindustan Zinc to invest $438 million to build reprocessing plant

Samarco gets court approval to exit bankruptcy proceedings

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Abcourt readies Sleeping Giant mill to pour first gold since 2014

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper