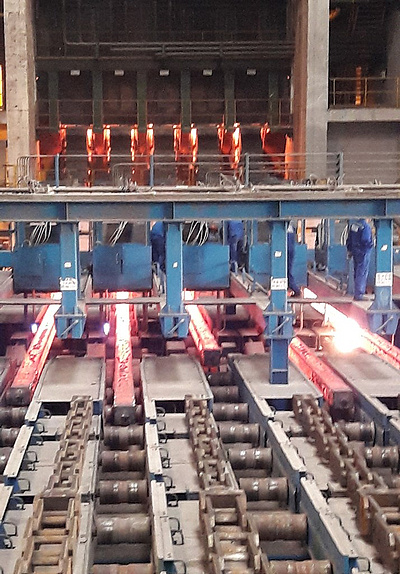

Continuous bloom caster modernized by Primetals Technologies receives FAC from Zenith Steel, China

The caster has an annual production of around 1.3 million metric tons of blooms with both round and square cross-sections. The objective of the modernization was to be able to cast an additional blank format with a rectangular cross-section of 280 x 320 millimeters. The blooms are then further processed into round bars in the company's own rolling mill, which has been specially adapted for this purpose.

Zenith Steel is privately owned and operates an integrated steel mill in Changzhou in the Jiangsu province of China. The company's steel mill has a production capacity of more than ten million metric tons of steel per year. Zenith Steel manufactures a wide range of end products, including steel pipes, bearing and spring steel, and various structural steels. Blooms with diameters of 400 and 500 millimeters are further processed into seamless pipes, while those with a diameter of 600 millimeters are used in the production of forging steels. The rectangular blooms are used for the manufacture of round bar steels.

In the course of the latest modernization, Primetals Technologies was responsible for the engineering of the mold required for the additional format and of the first two segments of the strand guide. The company also supplied new spray nozzles and side guides. In addition, the straightening unit, the dummy bars and the run-out area were adapted. Primetals Technologies also supervised the commissioning process. In a statement, Mr. Ren Zong Yi (任宗义), Project manager Zenith, highlighted the professional cooperation with Primetals Technologies.

The five-strand caster originally constructed by Primetals Technologies and first put into service in July 2013 was designed for the production of round blooms between 400 and 600 millimeters in diameter, as well as rectangular blooms with a cross-section of 370 x 490 millimeters. At a casting speed of up to 0.8 meters per minute, structural steels, high-carbon, alloy and low-alloy steels as well as pipe-grade steels can be cast. The continuous caster has a casting-bow radius of 14 meters and a metallurgical length of 32 meters. It is equipped with a curved mold, the DynaFlex hydraulic mold oscillator, and the LevCon mold level control. The drawing unit for rectangular blooms consists of seven drive units and operates with DynaGap Soft Reduction. This prevents center segregations and ensures a homogenous internal quality of the blooms.

Primetals Technologies engineered the continuous caster, supplied key components and technology packages, the complete basic and process automation, as well as the VAIQ quality management system. The scope of supply also included consultation services during construction and commissioning, as well as customer training.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook