Battery Cost Could Put the Brakes on Electric Car Sales

That is likely to happen by 2026, when the cost for lithium-ion battery packs is projected to fall to about $100 per kilowatt hour, Bloomberg reported.

The focus of the industry has moved from lithium-ion batteries using liquid electrolytes to solid-state ones, which address the need for safer and more powerful energy storage.

Toyota Motor Corp. has said it is working to commercialize the technology in the early 2020s, and Dyson Ltd. says it will build an electric car using solid-state batteries in three years.

The British company plans to invest $1.3 billion to develop the car, plus the same sum to create solid-state batteries for it. That investment would outpace those made by other major EV makers such as Tesla Inc.

Panasonic Corp. of Japan, BYD Co. of China and South Korea’s LG Chem Ltd. are the top manufacturers of lithium-ion batteries for EVs. Shares in companies such as lithium-salt maker Stella Chemifa Corp. and Sociedad Quimica y Minera de Chile SA, which mines chemicals including lithium, are on the rise.

As demand rises for metals used in batteries, beneficiaries include companies such as Japan’s Tanaka Chemical Corp., which manufactures and sells components for the storage devices.

The average cost of cars powered by fossil fuels is about $28,000, a figure that will probably rise to about $30,000 by 2030, based on estimates by Bloomberg New Energy Finance. To become cheap enough to replace that fleet, electric vehicles will rely on a 67% drop projected for battery costs in the next nine years.

Clean-car development is not just about plug-ins. Fuel cells such as those used in hydrogen-powered vehicles are slowly making an advance in China, which recently made an about-face in policy to support the technology.

The government opened a number of fuel-cell components to foreign investments, while taking EV battery cells and cathodes off the list.

The move on batteries squeezes out competition in China from companies based outside the country.

Hindustan Zinc to invest $438 million to build reprocessing plant

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

UBS lifts 2026 gold forecasts on US macro risks

Emirates Global Aluminium unit to exit Guinea after mine seized

Roshel, Swebor partner to produce ballistic-grade steel in Canada

Iron ore price dips on China blast furnace cuts, US trade restrictions

South Africa mining lobby gives draft law feedback with concerns

EverMetal launches US-based critical metals recycling platform

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

Trump raises stakes over Resolution Copper project with BHP, Rio Tinto CEOs at White House

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

Emirates Global Aluminium unit to exit Guinea after mine seized

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

Vulcan Elements enters US rare earth magnet manufacturing race

US seeks to stockpile cobalt for first time in decades

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Nevada army depot to serve as base for first US strategic minerals stockpile

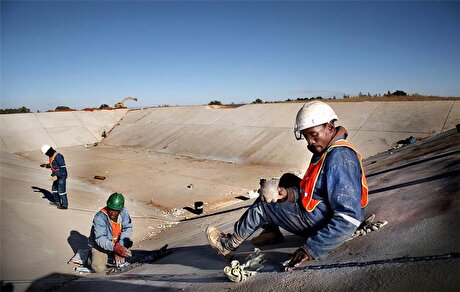

Tailings could meet much of US critical mineral demand – study