Reversing cold mill from SMS group on stream at Gunung Raja Paksi

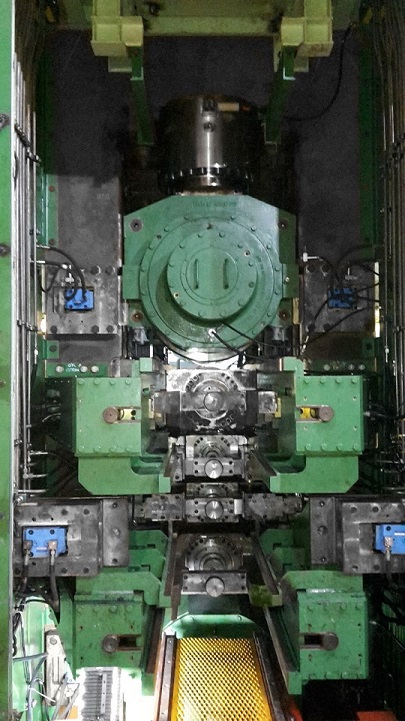

SMS group supplied the complete RCM in CVC®plus six-high design (CVC = Continuously Variable Crown), comprising mechanical equipment, X-Pact®electrical and automation systems and auxiliaries. Because all systems were supplied from a single source, their technology could be perfectly harmonized in order to support timely and smooth commissioning.

On the RCM GRP produces high-quality cold strips with a maximum width of 1,270 millimeters and a minimum final gauge of just 0.15 millimeters. The maximum capacity is 200,000 tons per year. The RCM gives GRP the opportunity to switch between reduction mode and skin-passing mode according to the product requirements.

SMS group’s rolling technologies like hydraulic adjustment, wedge adjustment, CVC®plus roll shifting technology in combination with positive and negative work and intermediate roll bending, entry and exit sides each with multi-zone cooling and dry-strip system, ensure high yield and product quality. A special contribution to efficient mill operation is the very compactly designed and therefore space-saving emulsion plant of the type Emulsion Compact Unit (ECU) by SMS group.

The X-Pact® automation with online level-2 system assures the fully automatic and efficient operation of the plant. These installations are completed by the X-Shape flatness measurement and control system arranged at the entry and exit sides.

After the successful production start, the commissioning team is working on further technical fine tuning in order to utilize the full capacity of the RCM.

On this flexible mill from SMS group, PT. Gunung Raja Paksi is able to manage both: rolling and skin passing.

The mill stand is the centerpiece of the RCM. It is provided with hydraulic adjustment, CVC®plus roll shifting, positive and negative work and intermediate roll bending.

The new, very compactly designed emulsion plant type ECU (Emulsion Compact Unit) of SMS group is convincing due to its high efficiency.

The first strip was successfully rolled and coiled on August 31, 2017.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook