Iran Steel Production Not Keeping Pace With Capacity Expansion

Although Iranian steelmakers are expanding capacity every year, production is not keeping pace.

According to Iranian Mines and Mining Industries Development and Renovation Organization, Iranian crude steel production capacity grew 32% from fiscal year March 2013-14 to 29.8 million tons in the last Iranian year (ended March 20, 2017) and is expected to reach 31 million by the end of the current fiscal year.

Steel production rose 15% during the same four-year period from 16.1 million tons to 18.5 million tons.

IMIDRO forecasts production to remain more or less the same this year. A comparison of steelmaking capacity and actual production brings into light the industry’s capacity utilization ratio, a key indicator of the sector’s health.

In capacity utilization, the Iranian steel industry has mostly moved against the global trend. The ratio’s only growth was recorded in the fiscal March 2014-15, as it grew from 72% the year before to 78%.

It has been on a downtrend ever since, dropping to 62% last year and is forecast to shed another 2% this year. The global utilization ratio, on the other hand, is recovering from its low of 65% in 2015 to 73% in 2016.

It is expected to stand at 72% for 2017, according to World Steel Association. What this indicates is that Iran is creating more steelmaking capacity than it can use, meaning higher operational costs and lower competitiveness.

This trend is likely to continue, considering that any growth in steel demand in the recession-hit construction sector, the main driver of steel consumption in Iran, seems unlikely to keep pace with steel expansion trend.

In its latest report titled "Short Range Outlook for 2017-18", the World Steel Association forecasts that Iranian steel demand will increase by 4.9% to 20.04 million tons in 2017 and increase to 6% in 2018 with 21.255 million tons.

Demand growth would still be too low to boost production. Here, exports may be the industry’s path to salvation, as they are the only alternative to the slump-stricken local market. Iranian mills exported over 3.74 million tons of semis and 1.79 million tons of steel products in the last fiscal year, registering a 108% and 16% growth respectively compared to the preceding year, the Iranian Steel Producers Association reported.

Thailand, the UAE, and Taiwan were the main customers of Iranian steel, accounting for 16%, 12% and 11% of 5.53 million tons of total exports, according to IMIDRO.

Italy with 9%, Oman with 7%, China with 7%, Iraq with 6%, Afghanistan with 5%, Jordan with 3%, Turkey with 3%, Egypt with 3%, Brazil with 3%, Spain with 2%, Morocco with 2% and Turkmenistan with 2% followed.

Iran's steel industry will need to further expand its overseas markets to maintain the feasibility of its expansion plans. It will have to tread cautiously though, as it was recently accused of dumping by European players due to a short-term spike in shipments to the green continent.

Although the European Commission finally decided not to impose preliminary duties on Iranian products back in April, the threat is still there. Industry experts believe EC’s threats might have also caused concerns about Iranian shipments for other steel importing countries.

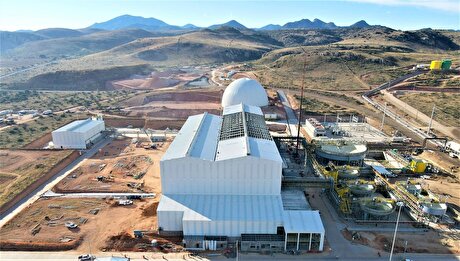

Nonetheless, the government seems intent on pursuing its ambitious steel capacity expansion plan to become the world’s sixth largest steelmaker, as part of its 20-Year Vision Plan (2005-25). It entails an annual production of 55 million tons of crude steel and 20-25 million tons of exports per year by the deadline.

Same Upstream Scenario

A higher steel production needs more iron ore and the Iranian government has made heavy investments in the sector. Accordingly, the same scenario of overcapacity can be witnessed here.

Iron ore concentrate production capacity grew 54% during the same four-year period under review to 44.35 million tons in the last fiscal year.

Production grew only about 30% during the period to stand at 31.36 million tons last year. This brings capacity utilization ratio to 71% from the high of 84% four years ago.

For pellets, output capacity grew 45% over the four years to reach 32 million tons last year. Production was up 23% to 25.62 million tons last year. Therefore, capacity utilization ratio stood at 80% last year, while it hovered above 95% for the three preceding years.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

SQM boosts lithium supply plans as prices flick higher

Pan American locks in $2.1B takeover of MAG Silver

Nevada army depot to serve as base for first US strategic minerals stockpile

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook