Emirates Global Aluminium Orders Seventh Hertwich Batch Homogenizing Unit

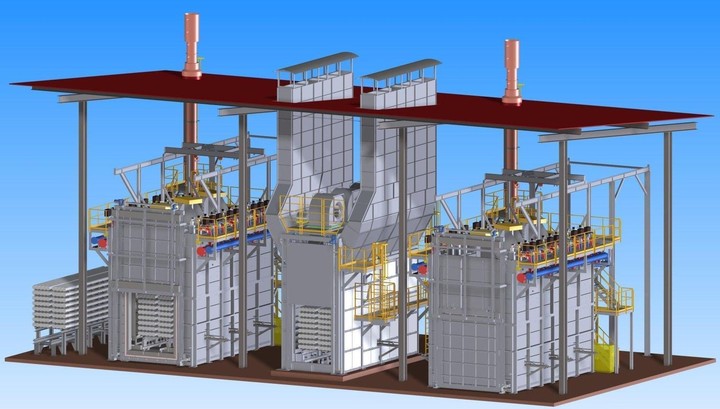

Batch homogenizing plant and cooling station, schematic view.

Emirates Global Aluminium is one of the largest industrial companies in the United Arab Emirates outside oil and gas. Its production makes the UAE the world’s fourth largest aluminum producing nation. EGA has smelters in both Jebel Ali in Dubai and Al Taweelah in Abu Dhabi.

The cooperation between EGA in Jebel Ali and Hertwich goes back to 1994, when the first continuous homogenizing plant was commissioned at EGA. In 2010, EGA was also the first company to place its trust in the newly developed Hertwich batch-furnace concept. Due to the positive experience gained, EGA is subsequently replacing all its older batch furnaces in Jebel Ali with modern units from Hertwich. The fourth unit started operation in the autumn of 2015; the batch furnace currently on order will be the fifth of its type at this aluminum plant. Including the two batch furnaces in operation at the Al Taweelah plant, EGA will soon operate a total of seven Hertwich batch homogenizing units.

The new furnace is designed for use with billets 125-406 millimeters in diameter and 5,000-8,000 millimeters long. During heating in a conventional batch furnace, the gas stream loses energy as it passes through the stack of material being heated; the new design achieves more uniform heating of the furnace contents by alternating the direction of the incident gas flow. Experience has shown that heating-up times can be reduced significantly in this way. A new feature of the fifth homogenizing unit is that certain alloys can also be cooled down in the furnace. The temperature range is 620-450 °C.

Where cooling is carried out in a separate cooling station, air from the casthouse is sucked in via fans and passed through the stack of material being cooled, the direction of the incident gas flow is alternated here too.

The ancillary equipment required for furnace operation has already been supplied with the existing furnaces and can be used for the new furnace. It facilitates a large degree of automation of the heat treatment process. This begins with the loading of the trolley and incorporates a whole host of subsequent steps: stacking with automated spacer handling, ultrasonic testing, furnace charging and operation, transfer to the cooling station and unloading the stack, sawing, weighing and packaging.

First Quantum scores $1B streaming deal with Royal Gold

Newmont nets $100M payment related Akyem mine sale

Caterpillar sees US tariff hit of up to $1.5 billion this year

Gold price rebounds nearly 2% on US payrolls data

Goldman told clients to go long copper a day before price plunge

Australia pledges $87M to rescue Trafigura’s Nyrstar smelters in critical minerals push

Copper price posts second weekly drop after Trump’s tariff surprise

One dead, five missing after collapse at Chile copper mine

Idaho Strategic rises on gold property acquisition from Hecla

Century Aluminum to invest $50M in Mt. Holly smelter restart in South Carolina

Australia to invest $33 million to boost Liontown’s Kathleen lithium operations

Glencore warns of cobalt surplus amid DRC export ban

SSR Mining soars on Q2 earnings beat

A Danieli greenfield project for competitive, quality rebar production

China limits supply of critical minerals to US defense sector: WSJ

Alba Hits 38 Million Safe Working Hours Without LTI

Advanced cold-rolled strip for China’s New Energy Vehicle market

Codelco seeks restart at Chilean copper mine after collapse

US slaps tariffs on 1-kg, 100-oz gold bars: Financial Times

Australia to invest $33 million to boost Liontown’s Kathleen lithium operations

Glencore warns of cobalt surplus amid DRC export ban

SSR Mining soars on Q2 earnings beat

A Danieli greenfield project for competitive, quality rebar production

China limits supply of critical minerals to US defense sector: WSJ

Alba Hits 38 Million Safe Working Hours Without LTI

Advanced cold-rolled strip for China’s New Energy Vehicle market

Codelco seeks restart at Chilean copper mine after collapse

US slaps tariffs on 1-kg, 100-oz gold bars: Financial Times