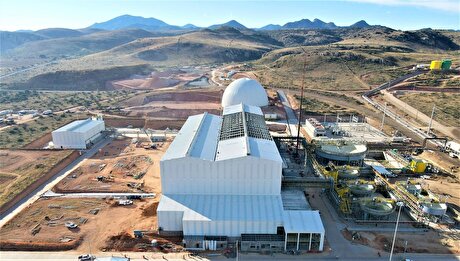

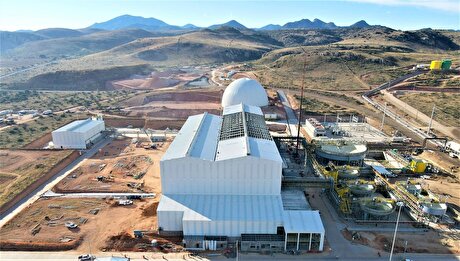

Mobarakeh steel; The record holder is the fastest time for the construction of a combined cycle power plant in the country/ Mobarakeh and Mapna steel manufacturer cooperation to solve a national challenge/ 98% progress of the first gas power plant

The manager of energy and fluids projects of Foulad Mobarake explained the latest developments of the combined cycle power plant of this company.

Hamidreza Khosravanipour said in this regard: Considering the country's electricity restrictions in the hot seasons of the year and as a result of the decrease in the production of Mubarakeh steel and the lack of profit due to the imposed electricity restrictions, the construction of this company's power plant was on the agenda since last year.

He said: Considering that in different seasons of the year, the restrictions of electricity, gas and water are effective in the production of Mobarakeh Steel Company, after expert investigations, the construction of a new generation combined cycle power plant, which has an efficiency of about 3 times compared to the previous generation power plants, with a planning It started exactly.

Mapna and Foulad Mobarakeh; together to build a unique power plant in the country

The manager of the energy and fluid projects of Mobarake Steel added: After the formation of technical and commercial committees, the contract for the construction of the combined cycle power plant of Mobarake Steel was concluded with Mapna, which is one of the most experienced companies in the construction of power plants in the country, and from the very beginning of the project, the project management team was formed. and multilateral coordination and interaction with Tovanir Company, Isfahan Regional Electricity and the use of experienced people in the client's team, supervision and contractor of the project in compliance with project management standards and defining the critical path of the project, the buoyancy of activities and overlaps of activities and daily monitoring of all critical path activities, At the same time as the workshop was equipped, executive activities started in parallel and were operationalized at an acceptable speed.

Mobarakeh steel; A leading steelmaker in energy production

Khosravanipour stated: In this project, Foulad Mobarakeh, as a private sector investor, has constructed a power plant, which will minimize the dependence of this company on the national network while providing a significant portion of the electricity required during the time of restrictions.

He emphasized: What is a difficult and significant task in such large projects is to create a communication management structure, including the contractor, employer, supervision, contractor, as well as procurement and equipment management, including transportation and inspection, purchase, management of financial resources, and forecasting payments and currency needs. ., managing human capital and complying with environmental and safety indicators, taking into account the risks of cyber and security attacks is one of the requirements of the project implementation, which with the help of Almighty God and detailed planning with the support of the management of Foulad Mobarakeh and the appreciable cooperation of Tovanir and Isfahan regional electricity companies and the efforts and hard work of the good project colleagues at Mapna Company, these planning and project matters were started and followed up at a good speed.

A fast and safe project

The manager of energy and fluids projects of Mobarakeh Steel stated: In this project, more than 117 thousand cubic meters of earth excavation and about 20 thousand cubic meters of concrete pouring, 2000 tons of metal frame were built, inspected and installed, and about 3000 tons of equipment in the first gas unit. And secondly, it has been established that this statistic is except for the executive activities in the field of electricity, automation and precision instruments and the executive affairs of the steam unit, which are being implemented in parallel and using the buoyancy of the activities.

He said: The record of the project's execution and very high speed is such that no gas power plant in the country has reached the synchronous and start-up stages in 16 months, and that is why this power plant is unique in its kind. According to the opinion of foreign technologists as well as previous experiences, it was not possible to build a power plant in the country and build a gas power plant in less than 24 months.

Mobarakeh Steel's partnership with 76 domestic companies to build a unique power plant

Khosravanipour said: The participation of 76 domestic companies to supply, manufacture, and install domestic equipment and localize sensitive equipment under the supervision of MAPNA is one of the other noteworthy points of this project. A power plant that uses less water and energy than existing power plants in the country due to the type of technologies used in it. In addition, one of the strengths of this project has been the safe working hours of around 2 million people. This project has already directly created employment for 800 people.

He added: Due to the fact that F-class power plants are not completely localized in the country, the provision of some foreign equipment faced problems. Currently, the first gas power plant is undergoing final tests and checks with 98% progress and will be synchronized and launched in the next month and ahead of schedule. Also, the second gas power plant, with a progress of 96.4 percent, is passing through the final stages for preparation and commissioning in about two months after the first power plant.

Gold price edges up as market awaits Fed minutes, Powell speech

Glencore trader who led ill-fated battery recycling push to exit

Emirates Global Aluminium unit to exit Guinea after mine seized

UBS lifts 2026 gold forecasts on US macro risks

Iron ore price dips on China blast furnace cuts, US trade restrictions

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

Afghanistan says China seeks its participation in Belt and Road Initiative

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Gold boom drives rising costs for Aussie producers

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Pan American locks in $2.1B takeover of MAG Silver

Iron ore prices hit one-week high after fatal incident halts Rio Tinto’s Simandou project

US adds copper, potash, silicon in critical minerals list shake-up

Barrick’s Reko Diq in line for $410M ADB backing

Gold price gains 1% as Powell gives dovish signal

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery