Shandong Iron & Steel Orders Continuous Caster for Ultra-wide Medium Slabs from SMS Group

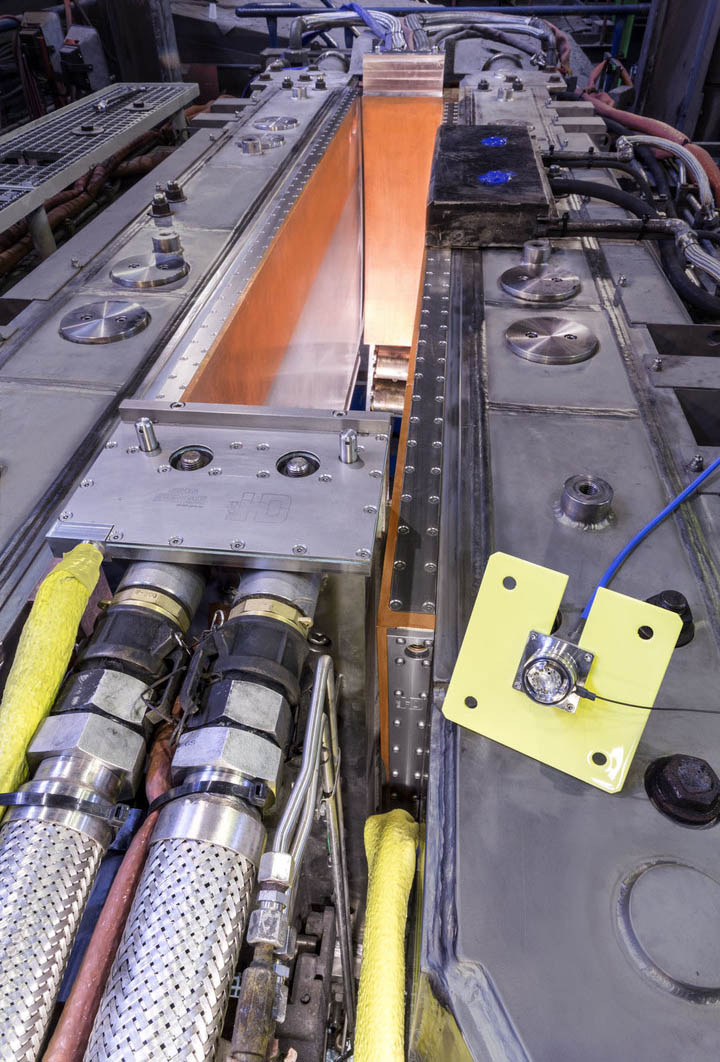

Reliable measurement of continuous caster segments and molds using the HD LASr plant assistant system from SMS group.

Shandong Iron & Steel Group Co Ltd, Rizhao, China, has placed an order with SMS group for the supply of a continuous caster for ultra-wide slabs. The single-strand caster is designed for an annual production of 1.5 million tons of steel slabs with widths of up to 3,250 millimeters and 150 millimeters thickness. On the caster, structural steel grades as well as micro- and low-alloy steel grades will be produced. Peritectic grades will make up more than 45 percent of the overall production. Commissioning is scheduled for the end of 2018.

In the future, Shandong Steel will measure and align molds and segments using the HD LASr assistant system developed by SMS group. Perfect alignment between molds and segments has a strong influence on slab quality.

Thanks to its three-dimensional laser measuring system and an intuitive operating concept, HD LASr ensures precise and reliable recording as well as a meaningful evaluation of the measured objects.

The molds will be treated with UNIGUARDTM, a plasma-ceramic coating which provides for a mold service life that is four times longer than with conventional coatings.

For this caster, SMS group will supply an HD moldTC (TC – thermocouples). Furthermore, the narrow sides will be equipped with HD moldFO (FO – Fiber Optical sensors) and the Breakout Prevention Assist and Mold Temperature Assist systems.

Breakout Prevention Assist reliably prevents break-outs resulting from stickers in the mold and in this way ensures effective protection and high availability of the plant. Mold Temperature Assist provides two- and three-dimensional information on distribution of the heat dissipation, alignment of the submerged entry nozzle, stirring effect and the contact between strand shell and copper plates.

Additionally, the mold will be equipped with HD moldFO copper plates that detect signals by means of optical fibers. More than 500 measuring points are distributed across the entire height of the mold. Direct visualization of the local strand shell thickness and the respective thickness of the liquid and solid layers of mold powder is only possible using HD moldFO. This provides for a deeper understanding of the solidification process.

SMS group will supply the entire X-Pact® electrical and automation systems for the continuous caster, the technological control systems (Level 1) and the technological process models (Level 2).

Furthermore, the plant will be equipped with Internet of things (Industry 4.0) technologies newly developed by SMS group providing for intelligent processing of plant data and automation of processes. Based on the steel grades to be produced, the X-Pact® TechAssist system automatically selects the optimum technological parameter settings for the metallurgical process. X-Pact® Process Guidance automatically provides all relevant process information, prompts and operator screens at the right time. All plant control and maintenance functionalities can be performed comfortably at an operator station. X-Pact® Business Intelligence summarizes relevant data from different systems and enables interaction with dynamic applications and dashboards.

The SMS group scope of supply furthermore comprises training of the customer personnel, local manufacturing supervision, installation and installation supervision as well as commissioning supervision.

With the HD moldFO from SMS group, among other things the strand shell thickness can be visualized.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook