Turmec installs MRF plant in Wiltshire to treat recyclable materials

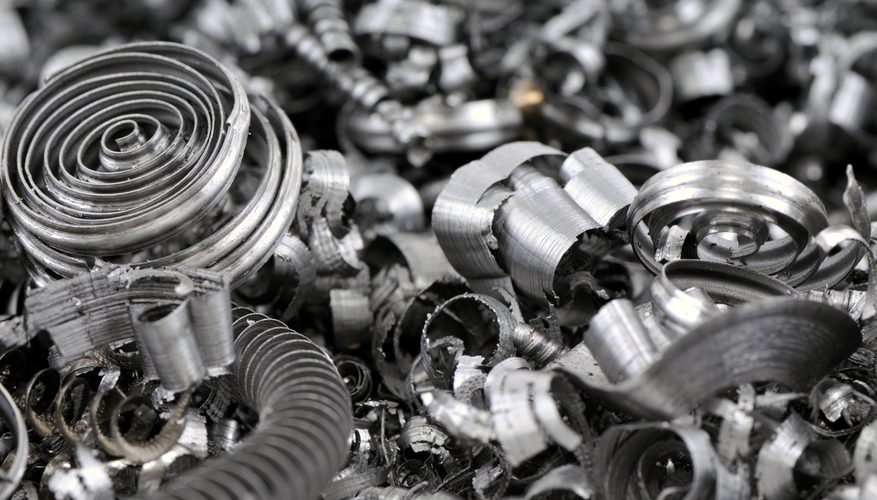

Turmec’s advanced sorting equipment includes various screens with optical and magnet elements to maximise the recovery of paper, cardboard, plastic bottles, plastic pots, tubs and trays, steel and aluminium cans, food and drink cartons.

The MRF’s plant and personnel are ready to recover materials of the highest quality for reprocessing. Comingled recyclables will be sorted in a single pass into 10 separate products for recycling. Incoming materials will be loaded into a bag splitter that opens the bags and loosen materials before fed onto the sorting line. The plant also has a quality control station that ensures the suitability of materials being fed to the plant.

Plastics, cans, and cartons are separated using screens, optical separators, magnets, eddy currents, and further picking stations before the final products drop into gated storage bunkers and a central conveyor moves all materials from bunkers to the baler.

Anthony Clune, Turmec’s Senior Project Manager, said: “This was a challenging and very rewarding project due to timelines and space but now, our client’s plant can achieve high standards in all products – in excess of 98 per cent purity.”

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook