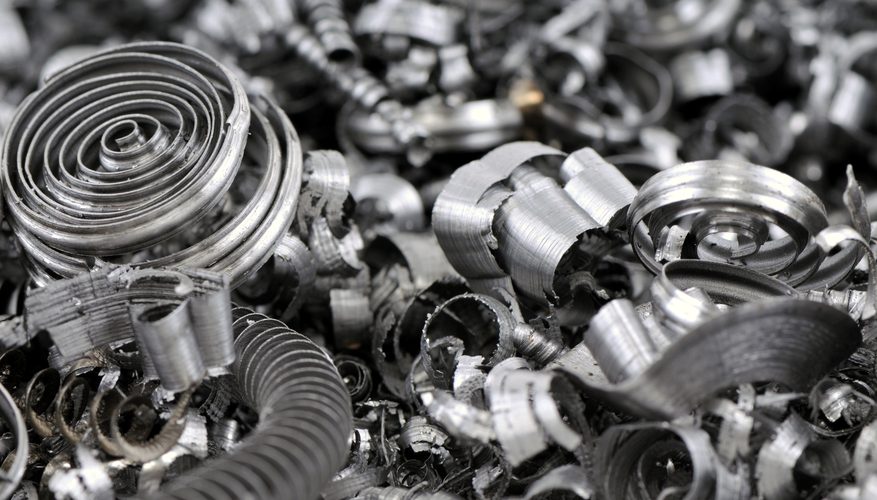

Tungsten carbide scrap hits new lows amid headwinds

Declining APT prices in recent weeks discourages reclamation of concentrate material from tungsten carbide scrap by providing a lower-priced feedstock material for tungsten products.

The US carbide scrap market is coming off a period of high scrap generation and while demand is waning for carbide tools. A large increase of carbide imports grew domestic inventories, while the economic incentives to utilize these products are declining.

Average monthly export prices from China for APT in July reached the lowest levels in over two years at $197-207/mtu. Prices fell 23pc from the average monthly price of $255-265/mtu in January 2019.

US processor buying prices for tungsten carbide scrap inserts and rounds dropped to $5.00-6.00/lb in August from $7.25-8.25/lb a month earlier. The 29pc drop marks the lowest price for the carbide scrap rounds and inserts since the end of January 2009.

Processors said that carbide scrap is not being recycled for APT at similar volumes than in previous years owing to a lack of demand from domestic and offshore consumers.Market participants could import lower-priced APT as a feedstock to manufacture tungsten products without the need to reclaim the material from carbide scrap for resale. Despite pressure from cheap imported APT, consumers contend that carbide scrap recyclers would not stop production to purchase APT in lieu of refining scrap for the material.

The rise and fall of tungsten carbide scrap prices in the US in the last decade is strongly correlated with fluctuations in APT export prices in China. US processor margins get squeezed when the price of APT declines and price spreads between the two sources of tungsten material tighten.

Additionally, as APT prices start to rise, so typically does the volume of tungsten carbide imported into the US, and the opposite is generally true when APT prices begin to drop.

Year-to-date US imports of tungsten carbide totaled 1,062 metric tonnes (t) through June, 68pc higher than the prior 10-year average volume over the same period and on pace to set a record high since the International Trade Commission adopted the harmonized tariff system in 1989.

China's market share of US tungsten carbide imports have not deviated significantly over the last 10 years, and the price per unit of quantity is generally slightly below the average price for all tungsten carbide imports.

In terms of exports, China imposed retaliatory tariffs on the US including on exports of "scrap generated in machining" and "tungsten waste." US exports of tungsten waste and scrap to China fell to zero in July 2017, with none shipped since.

While US exports dropped off completely, China accounted for almost 48pc of US tungsten carbide imports in the first half of 2019, the largest share since 2013.

Typically carbide scrap shipped to China would be re-manufactured into cutting tools for export to the US. After-market uses for re-manufactured carbide tools from carbide scrap serve machining shops, machinery manufacturers, and the oil and gas industry.

According to Federal Reserve data, oil and gas drilling and machine shop production reached their highest levels since March 2015, after recently peaking in November 2018 and March 2019, respectively. Machinery manufacturing capacity utilization reached its' highest level since September 2012 in the month of November 2018.

All three rates are declining from multi-year highs reached within the last six to seven months, a trend which mirrored the decline of carbide scrap prices in previous downturns in 2009 and 2016. The significant difference between 2009 and 2016 is the global economic recession of 2008 and the recession in the oil and gas industry in late 2015 precluded and exacerbated the drops in prices owing to macroeconomic factors.

Upward swings in these metrics typically indicate an increase of scrap generation as well as an increased demand for carbide tools, whether manufactured from imported tungsten carbide or refurbished carbide scrap. An oversupply of inventory typically follows when these rates start to descend. For instance, carbide scrap prices declined for 17 of the following 18 months starting September 2014 as all three rates declined precipitously from multi-year highs from the end of 2014 to when the price bottomed out January 2016.

Moreover, an abundance of imported, virgin carbide material will provide ample stocks for machine shops and drilling tool consumers to use in the near term should demand strengthen in addition to the absence of China as a buyer of carbide scrap material.

APT prices, as well as prices for other concentrates, would typically need to rise to incentivize reclamation operations or machining and drilling rates would likely need to halt declines to utilize the inventory of imported, virgin material before re-manufacturing of carbide tools is a viable option for the scrap aftermarket.

Codelco seeks restart at Chilean copper mine after collapse

Hudbay snags $600M investment for Arizona copper project

Uzbek gold miner said to eye $20 billion value in dual listing

BHP, Vale offer $1.4 billion settlement in UK lawsuit over Brazil dam disaster, FT reports

Peabody–Anglo $3.8B coal deal on the brink after mine fire

A global market based on gold bars shudders on tariff threat

SSR Mining soars on Q2 earnings beat

Minera Alamos buys Equinox’s Nevada assets for $115M

Century Aluminum to invest $50M in Mt. Holly smelter restart in South Carolina

Samarco gets court approval to exit bankruptcy proceedings

US eyes minerals cooperation in province home to Reko Diq

Allegiant Gold soars on 50% financing upsize

Explaining the iron ore grade shift

Metal markets hold steady as Trump-Putin meeting begins

Trump to offer Russia access to minerals for peace in Ukraine

Gemfields sells Fabergé luxury brand for $50 million

Gold price stays flat following July inflation data

Eco Oro seeks annulment of tribunal damage ruling

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Samarco gets court approval to exit bankruptcy proceedings

US eyes minerals cooperation in province home to Reko Diq

Allegiant Gold soars on 50% financing upsize

Explaining the iron ore grade shift

Metal markets hold steady as Trump-Putin meeting begins

Trump to offer Russia access to minerals for peace in Ukraine

Gemfields sells Fabergé luxury brand for $50 million

Gold price stays flat following July inflation data

Eco Oro seeks annulment of tribunal damage ruling