Pakistani’s largest environmental-friendly steel melting furnace for AGHA Steel Industries

From left to right Mr. Hussain Agha, Executive Director of Agha Steel Industries; Dr. Miftah Ismail, Minister of State/Chairman Board of Investment; Mr. Stefano Pontecorvo, Ambassador of Italy; Mr. Marco Sattolo, Director of Sales, Danieli Centro Met.

The Italian Embassy in Islamabad hosted the signing ceremony of the contract for the meltshop enhancement project between Agha Steel Industries, Pakistan and Danieli, Italy.

The project includes the complete reconstruction of the Electric Arc Furnace (EAF) and a new fume treatment plant.

Agha Steel Industries is the only private steelmaker running a minimill in Pakistan, and from 2011 has reached a very important position in a market with a growing demand for quality construction steel.

The targets of the project are the reduction of the electrical consumption and tap-to-tap time, in order to increase productivity at a lower production cost.This will be achieved with the modernization of the EAF which will feature the installation of a set of technological packages such Q-Reg+ and ISAC.Q-Reg+ is a top performing electrode regulator integrating a slag foaming management system, while the ISAC Integrated Scrap Automatic Charging system will allow Agha Steel to reduce the number of buckets charged in the EAF from three to one.A new chemical package will allow a more efficient utilization of the chemical energy in the furnace.

Agha Steel, committed to an environmental friendly steelmaking, will operate a new Danieli Environment fume dedusting system.

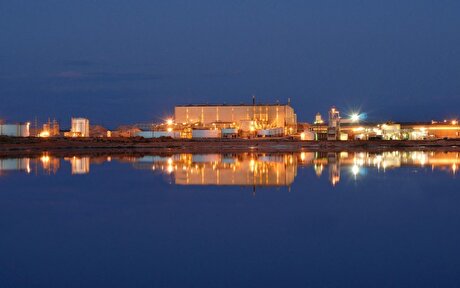

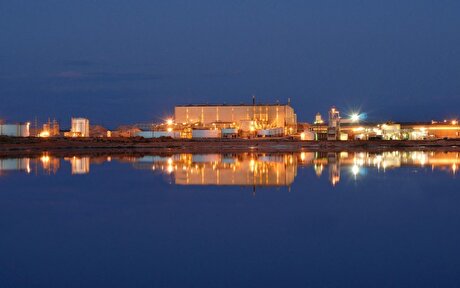

NexMetals receives EXIM letter for potential $150M loan

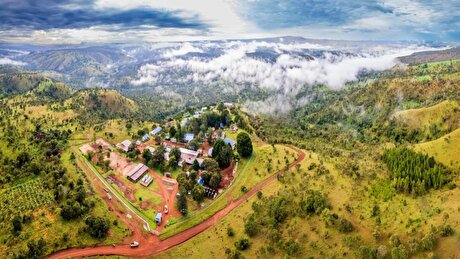

Lifezone Metals buys BHP’s stake in Kabanga, estimates $1.6B project value

BHP delays Jansen potash mine, blows budget by 30%

China quietly issues 2025 rare earth quotas

BHP, Lundin JV extends useful life of Argentina copper mine

Gold price eases after Trump downplays clash with Fed chair Powell

Northern Dynasty extends losses as it seeks court resolution on Pebble project veto

KoBold signs Congo deal to boost US mineral supply

Spring Valley gold project in Nevada gets federal approval

Teck approves $2.4B expansion of Highland Valley Copper

Titan Mining targets Q4 2025 to become only integrated US graphite producer

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Saskatchewan Research Council adds full-scale laser sorter to mining industry services

Copper price hits new record as tariff deadline looms

Glencore workers brace for layoffs on looming Mount Isa shutdown

Resolute publishes initial resource for satellite deposit near Senegal mine

Brazil producers look to halt pig iron output as US tariff threat crimps demand

US targets mine waste to boost local critical minerals supply

Gold price eases after Trump downplays clash with Fed chair Powell

Titan Mining targets Q4 2025 to become only integrated US graphite producer

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Saskatchewan Research Council adds full-scale laser sorter to mining industry services

Copper price hits new record as tariff deadline looms

Glencore workers brace for layoffs on looming Mount Isa shutdown

Resolute publishes initial resource for satellite deposit near Senegal mine

Brazil producers look to halt pig iron output as US tariff threat crimps demand

US targets mine waste to boost local critical minerals supply

Gold price eases after Trump downplays clash with Fed chair Powell