SMS group successfully commissioned the Compact Cold Mill at Aisha Steel Mills Limited

The CCM® at ASML is designed for an annual cold strip production capacity of 500,000 tons. The new facility enables ASML to supply the local market with high-grade cold strip according to international standards and helps the company to make its contribution to reducing the country`s dependency on high-quality cold strip imports. The products rolled on the CCM® are up to 1,250 millimeters wide and down to 0.15 millimeters thin.

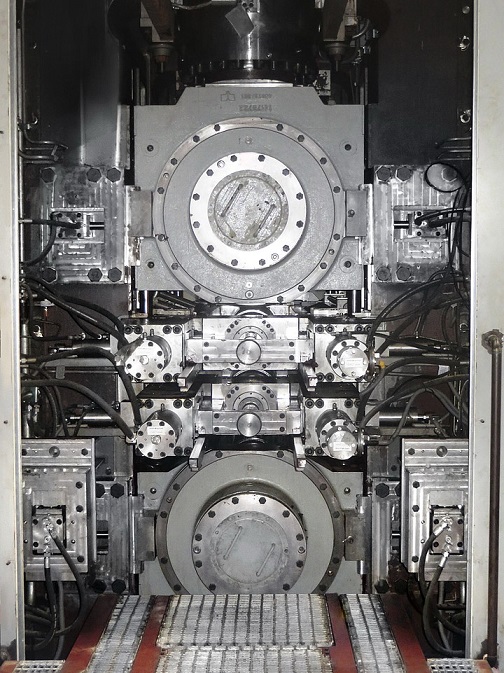

The CCM® features two mill stands in four-high design with the proven roll shifting technology CVC®plus (Continuously Variable Crown) by SMS group. CVC®plus is supplemented by further actuators to infinitely adjust the roll gap, for example positive and negative work roll bending. The quality-determining technical highlights of the plant include two X-Shape flatness measurement rolls, installed at the entry and exit sides, together with multi-zone cooling system and automatic flatness control.

The highly productive CCM® is equipped with the holistic X-Pact® electrical and automation system from SMS group. SMS group supplied the complete plant with all auxiliary equipment, such as modern technological instrumentation, emulsion plant, high- and low-pressure hydraulics as well as the fume exhaust system.

With this CCM® from SMS group, ASML operates a high-quality and modern plant technology suited to meet present and future requirements.

One of the two mill stands in CVC®plus four-high design.

On May 17, 2019, the first coil was successfully rolled on the new CCM® of Aisha Steel and was signed by the members of the project team.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook