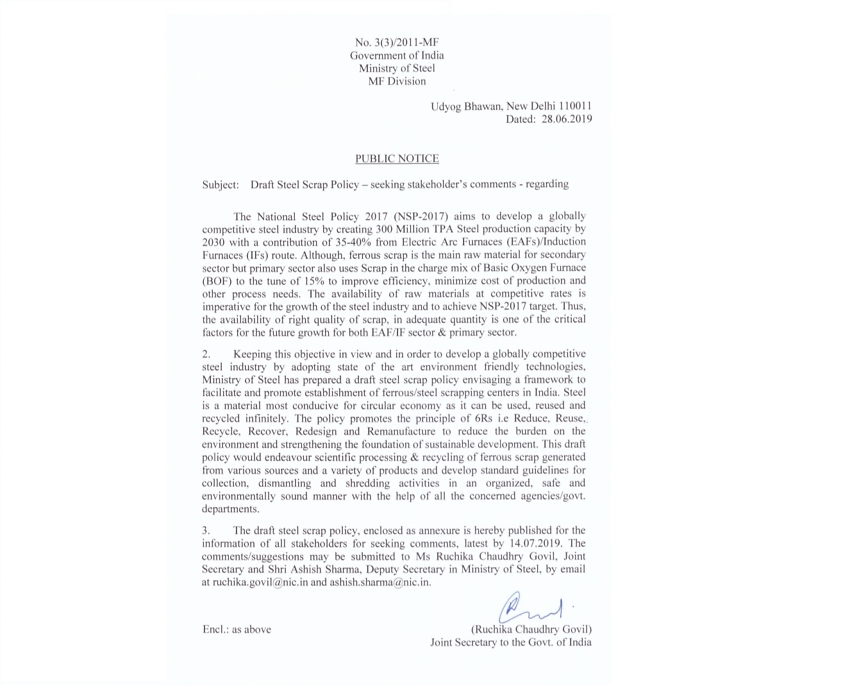

India: Ministry of Steel Invites Comment on Draft Steel Scrap Policy

Why is the need for scrap ?

While iron ore remains the primary source of steel making, used or re-used steel in the form of Scrap is the secondary raw material for the steel industry. Indian steel industry is characterized by the presence of a large number of small steel producers who utilize scrap with other inputs in Electric Arc Furnaces (EAFs)/ Induction Furnaces (IFs) for steelmaking. As on March 2019, 1128 EAFs & IFs are operating in the country and largely depend upon scrap as a raw material to produce steel.

How Steel Scrap policy will benefit the industry?

This will ensure scientific processing & recycling of ferrous scrap generated from various sources and a variety of products. The policy framework shall provide standard guidelines for collection, dismantling and shredding activities in an organized, safe and environmentally sound manner.

How is Indian scrap demand?

The availability of scrap is a major issue in India and in 2017 the deficit was to the tune of 7 million Tons. The gap between demand and supply is likely to be reduced in the future and the country may be self-sufficient by 2030.

The efficient use of scrap for steel production becomes very crucial for India as 35-40% share has been envisaged from scrap-based steel production in the journey of 300 million TPA by 2030. This shall increase requirement of steel scrap from present level of around 25 million tones to more than 50 million tons by 2030. This is mainly because with the increase in consumption of steel in the recent past and ELVs, the generation of scrap is likely to be increased considerably. This scrap has to be channelized so that the same can be utilized for steel production in an environmental friendly manner.

How will the working model be?

The increased production of vehicles and increased use of consumer durable white goods in the last two decades and their rapid obsolescence shall generate large quantities of end of life products. This shall result in the generation of a continuous flow of large ferrous scrap for recycling in steel production.

The collection and/or dismantling center should either setup by or be associated with a scrap processing center.

Logistics may be one of the main challenges for safe and cost-effective system for inbound unprocessed products/scrap and outbound processed scraps to the melting shops. Thus, scrapping centres (Collection cum dismantling centre and recycling centre) need to be supported by an adequate logistic facility in consonance with the National Logistic Policy.

Codelco seeks restart at Chilean copper mine after collapse

Hudbay snags $600M investment for Arizona copper project

Uzbek gold miner said to eye $20 billion value in dual listing

BHP, Vale offer $1.4 billion settlement in UK lawsuit over Brazil dam disaster, FT reports

Peabody–Anglo $3.8B coal deal on the brink after mine fire

A global market based on gold bars shudders on tariff threat

SSR Mining soars on Q2 earnings beat

Minera Alamos buys Equinox’s Nevada assets for $115M

Century Aluminum to invest $50M in Mt. Holly smelter restart in South Carolina

Samarco gets court approval to exit bankruptcy proceedings

US eyes minerals cooperation in province home to Reko Diq

Allegiant Gold soars on 50% financing upsize

Explaining the iron ore grade shift

Metal markets hold steady as Trump-Putin meeting begins

Trump to offer Russia access to minerals for peace in Ukraine

Gemfields sells Fabergé luxury brand for $50 million

Gold price stays flat following July inflation data

Eco Oro seeks annulment of tribunal damage ruling

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Samarco gets court approval to exit bankruptcy proceedings

US eyes minerals cooperation in province home to Reko Diq

Allegiant Gold soars on 50% financing upsize

Explaining the iron ore grade shift

Metal markets hold steady as Trump-Putin meeting begins

Trump to offer Russia access to minerals for peace in Ukraine

Gemfields sells Fabergé luxury brand for $50 million

Gold price stays flat following July inflation data

Eco Oro seeks annulment of tribunal damage ruling