Outotec® Concentrate Burner - New ways to reduce the need for manual maintenance with the help of Outotec® Flashguard

If the process air distribution is not optimal, the furnace campaign times can also be noticeably shorter. A misaligned burner can result in increased weak acid production as well, as was learned at the Atlantic Copper Huelva smelter after the 2011 shutdown (refer to Figure 19 in 13th Flash Conference Article “A Review of recent improvements to control weak acid production at the Huelva smelter) . Before the introduction of the Outotec® FlashGuard a few years ago, measuring the alignment required quite a bit of manual work using the chain & ball tool, results of which might vary based on the user as well.

Our first generation FlashGuard enabled the online measurement of the burner’s alignment with the help of digital cameras and sophisticated machine vision algorithms. Now the second generation of the Outotec® FlashGuard has been further developed based on customer feedback and experiences. In this latest design the cameras are easier to retrofit to the air chamber without modifications to the air chamber’s roof as the camera boxes can be installed on the existing air chamber inspection windows. Additionally adjusting the cameras during commissioning and maintenance is now easier and the cameras are updated to higher resolution models, which can withstand higher operating temperatures.

The estimates of the current buildup conditions on the visible surfaces are also provided by the system. The results are calculated as easy to understand percentage KPI’s as “alignment efficiency” and “buildup prevention efficiency”. These results are available through OPC for the client for further use and analysis.

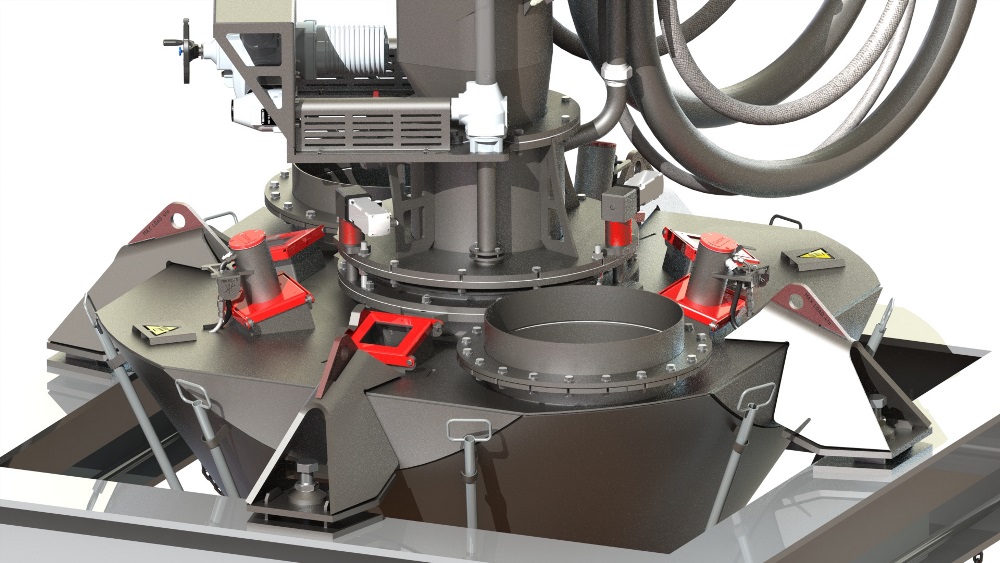

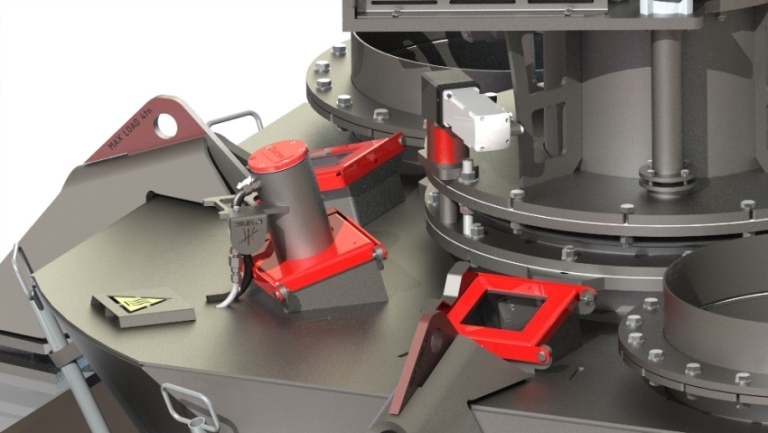

Still the single feature we’re most enthusiastic about is the new optional automatic concentrate or matte burner alignment system (patent pending), which removes the need for traditional “measure, adjust, re-measure, re-adjust” - workflow and hence significantly reduces the manual work and downtime required for the task and aligns the results by removing the human aspects. The alignment and buildup measurements from the FlashGuard system are automatically utilized in the alignment control of the burner so that the burner is always properly aligned to the center of the guiding cone so that the process air flow to the reaction shaft is as even as possible. The arrangement with three servo motors adjusting the alignment of the burner based on the FlashGuard measurements is illustrated in the figures 1 and 2 below.

Figure 1: Outotec Concentrate Burner with FlashGuard and automated centricity adjustment feature.

Figure 1: Outotec Concentrate Burner with FlashGuard and automated centricity adjustment feature.

Figure 2: Close-up of the FlashGuard camera box installed on an existing inspection window. In this example servomotors are used to adjust the concentrate burner's alignment. Adjacent manual screws as a backup adjustment and as mechanical limiters.

Like the FlashGuard system’s cameras, the new burner alignment option is straightforward to retrofit into an existing Outotec concentrate or matte burner: only the flexible bellow together with the servo motors is required. The existing flexible bellow is simply replaced with the servo equipped flexible bellow - this way the system can be preinstalled on the spare CJD in the workshop and taken into use during a CJD changeover.

First Quantum scores $1B streaming deal with Royal Gold

Newmont nets $100M payment related Akyem mine sale

Caterpillar sees US tariff hit of up to $1.5 billion this year

Gold price rebounds nearly 2% on US payrolls data

Goldman told clients to go long copper a day before price plunge

Australia pledges $87M to rescue Trafigura’s Nyrstar smelters in critical minerals push

Copper price posts second weekly drop after Trump’s tariff surprise

One dead, five missing after collapse at Chile copper mine

Idaho Strategic rises on gold property acquisition from Hecla

Century Aluminum to invest $50M in Mt. Holly smelter restart in South Carolina

Australia to invest $33 million to boost Liontown’s Kathleen lithium operations

Glencore warns of cobalt surplus amid DRC export ban

SSR Mining soars on Q2 earnings beat

A Danieli greenfield project for competitive, quality rebar production

China limits supply of critical minerals to US defense sector: WSJ

Alba Hits 38 Million Safe Working Hours Without LTI

Advanced cold-rolled strip for China’s New Energy Vehicle market

Codelco seeks restart at Chilean copper mine after collapse

US slaps tariffs on 1-kg, 100-oz gold bars: Financial Times

Australia to invest $33 million to boost Liontown’s Kathleen lithium operations

Glencore warns of cobalt surplus amid DRC export ban

SSR Mining soars on Q2 earnings beat

A Danieli greenfield project for competitive, quality rebar production

China limits supply of critical minerals to US defense sector: WSJ

Alba Hits 38 Million Safe Working Hours Without LTI

Advanced cold-rolled strip for China’s New Energy Vehicle market

Codelco seeks restart at Chilean copper mine after collapse

US slaps tariffs on 1-kg, 100-oz gold bars: Financial Times