Danieli Riverside Carbon Series alloy outclasses competition by doubling capacity

Vice President of Iowa-based Danieli Riverside Products said: “One of our customers who had been running manganese hammers achieved 2.4 times the life with the Carbon Series. On acquisition costs of material, that leads to a 50 per cent reduction in cost per ton, but increased wear life also brings more consistent density and production over a longer time, and reduces the number of times the shredder has to be shut down or accessed for maintenance.”

The Carbon Series was developed specifically to offer extended wear life. The proprietary alloy mix is heat treated to improve strength, while torque has been increased by 15 per cent by shifting the centre of mass down into the body of the hammer. Eye orientation has also been changed to improve access. He explained: “The idea behind it was to make all other hammers obsolete and we think we have succeeded in that.”

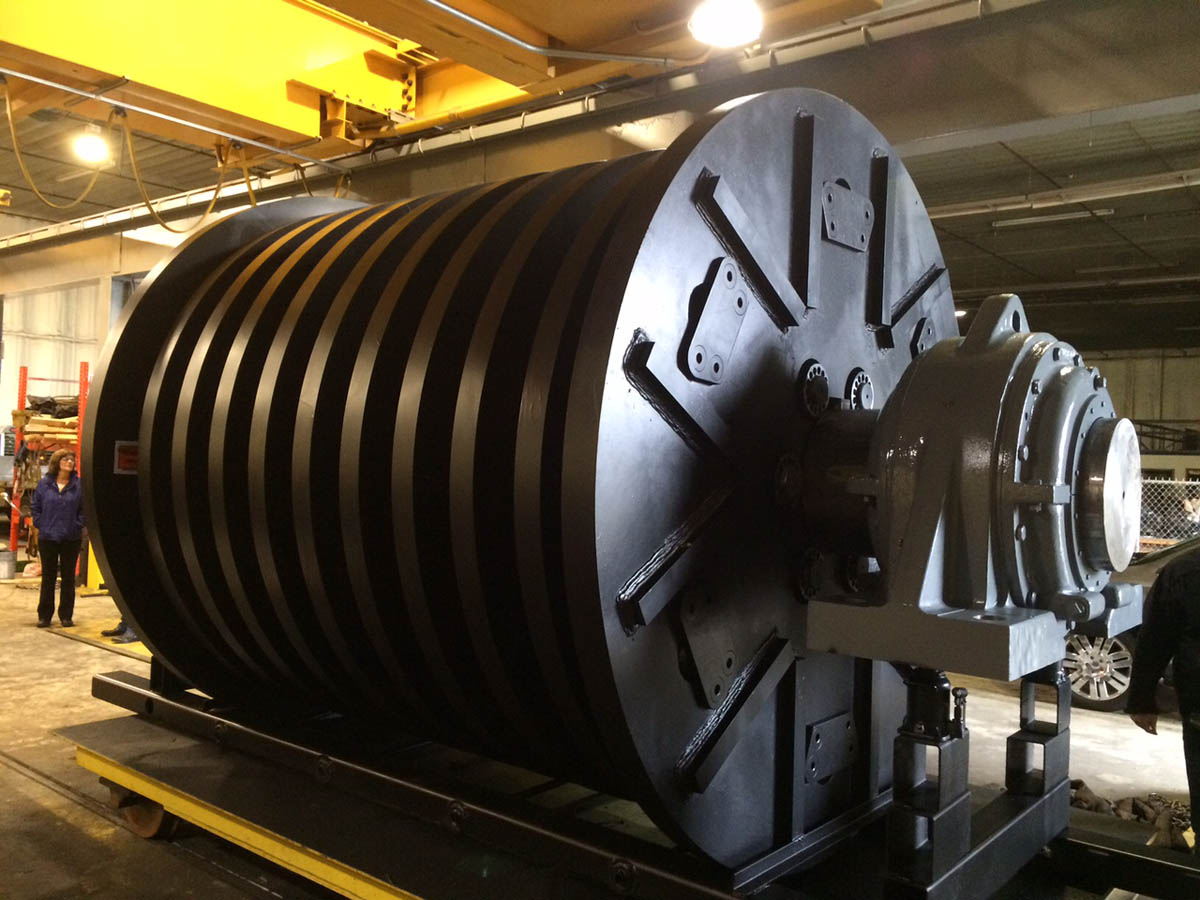

Danieli Riverside Products (DRS) has also recently developed Carbon Series rotors. Twelve of these have been shipped as widely as Equador and Norway and are expected to provide the same advantages and benefits as the wear parts. DRS VP said: “They are very versatile. We have supplied large steelmakers and a small independent, and they are all looking for the same thing. Nothing is maintenance free, but our rotors are as close to maintenance free as you can hope to find – there is no welding required at all.”

Overall, he described the driver behind the Carbon Series alloy as “the search for the lowest cost per ton”, and added: “Within our core business – shredders – the wear parts or consumables take all the impact. If you can take an operation that’s running 5,000 tons on a set of hammers and get them to 10,000 tons, then you will reduce their cost per ton based on the acquisition of the material. But you will also give them the cost savings of running twice as long without having to shut down the shredder.

So we are providing increased production and less cost in terms of maintenance and having to shut the shredder down when you make those hammer changes. For customers the effect is a more smooth running operation, with significantly lower costs.”

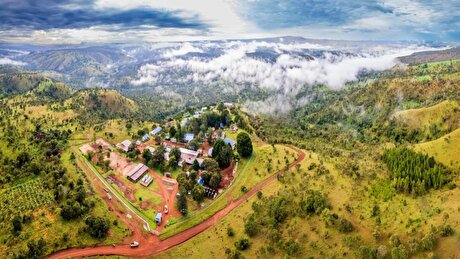

Crow Wing Recycling in Minnesota is a recent success story. Since the Vanwyngeeren family bought the company in 1996, the number of employees has risen six-fold while the operation has expanded from just one site to four. In 2010, Crow Wing acquired its first shredder; two years later it switched to DRS carbon series hammers, doubling its tonnage on the life of the hammer and reducing downtime and labour costs.

Vice President Grant Vanwyngeeren said: “In our industry, shredding is always about cost per ton. Especially in tough times like today’s market, you have to start looking at ways to lower your expenses and production costs. We are getting up to three times the life out of the carbon series hammers, so even though the hammer has a greater up-front cost, it is still far significantly for the bottom line.”

Crow Wing Recycling

Crow Wing Recycling offers a comprehensive service to a wide range of customers, including a drive-in facility and on-site collection boxes. Introducing a shredder to the outfit allowed it to offer value to other scrap facilities. The original, standard manganese hammers provided up to 4,000 tons, with flipping and switching taking place every other day whereas the carbon series replacements shred up 10,000 tons.

The cost implications are obvious, but Vanwyngeeren says the benefits are more complex: “In 2012, we took a 12-hammer trial order. After two days of shredding, which was typically when we were ready to flip and switch, we opened the mill and the hammers were in almost new condition. We used to be in the mill every other day, now we do hammer work every four days. It has more than doubled our tons on the hammers, but also reduces risk – it’s when guys are in the shredder that accidents can happen, so the more we reduce the time spent in the shredder, the safer our operation will be.”

The relationship between Crow Wing and Danieli Riverside goes back to 2012, when Crow Wing ordered a spare rotor to back up their original shredder purchase. Unfortunately, six weeks before the new rotor was due to arrive, the installed rotor was damaged in an incident with an unshreddable item. Riverside pulled out all the stops to provide the replacement earlier than planned and within 10 days Crow Wing was up and running again.

Looking to the future, Vanwyngeeren is aiming for further expansion. “We have three small feeder yards now, plus the main facility. We would love to have seven or eight facilities and become more self-sufficient in scrap supply.”

To others considering the options for hammer replacement, he said: “You need to look past the initial cost of alloy hammers. If you buy a 10-hammer sample, they will outperform manganese and other hammers; they will prove a winner when it comes to lowering cost per ton on hammer life.”

NexMetals receives EXIM letter for potential $150M loan

Lifezone Metals buys BHP’s stake in Kabanga, estimates $1.6B project value

China quietly issues 2025 rare earth quotas

BHP delays Jansen potash mine, blows budget by 30%

Gold price eases after Trump downplays clash with Fed chair Powell

BHP, Lundin JV extends useful life of Argentina copper mine

Teck approves $2.4B expansion of Highland Valley Copper

KoBold signs Congo deal to boost US mineral supply

Northern Dynasty extends losses as it seeks court resolution on Pebble project veto

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions

Pilot Mountain tungsten project in Nevada gets $6M from Department of Defense

Adriatic boosts output but trims forecast ahead of Dundee deal

Peru mulls green light for $6 billion in mining projects

Majestic Gold halts Chinese mine following fatal accident

Energy Fuels’ rare earth JV in Australia receives regulatory OK

Torex Gold buys Prime Mining in $327M Mexico expansion

US targets mine waste to boost local critical minerals supply

Copper price pulls back sharply ahead of US tariff deadline

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions

Pilot Mountain tungsten project in Nevada gets $6M from Department of Defense

Peru mulls green light for $6 billion in mining projects

Majestic Gold halts Chinese mine following fatal accident

Energy Fuels’ rare earth JV in Australia receives regulatory OK

Torex Gold buys Prime Mining in $327M Mexico expansion

US targets mine waste to boost local critical minerals supply

Copper price pulls back sharply ahead of US tariff deadline